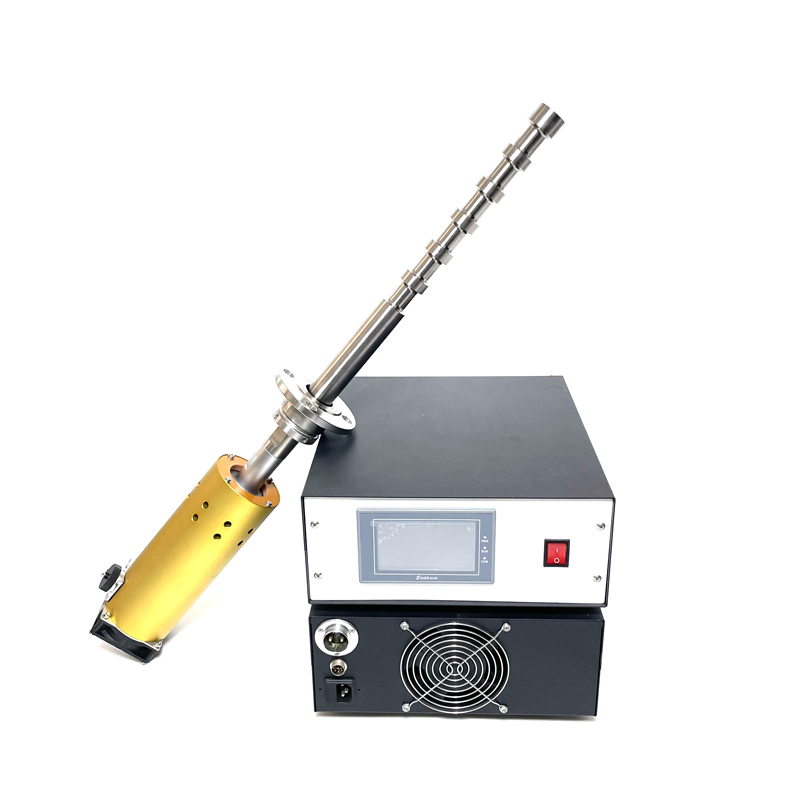

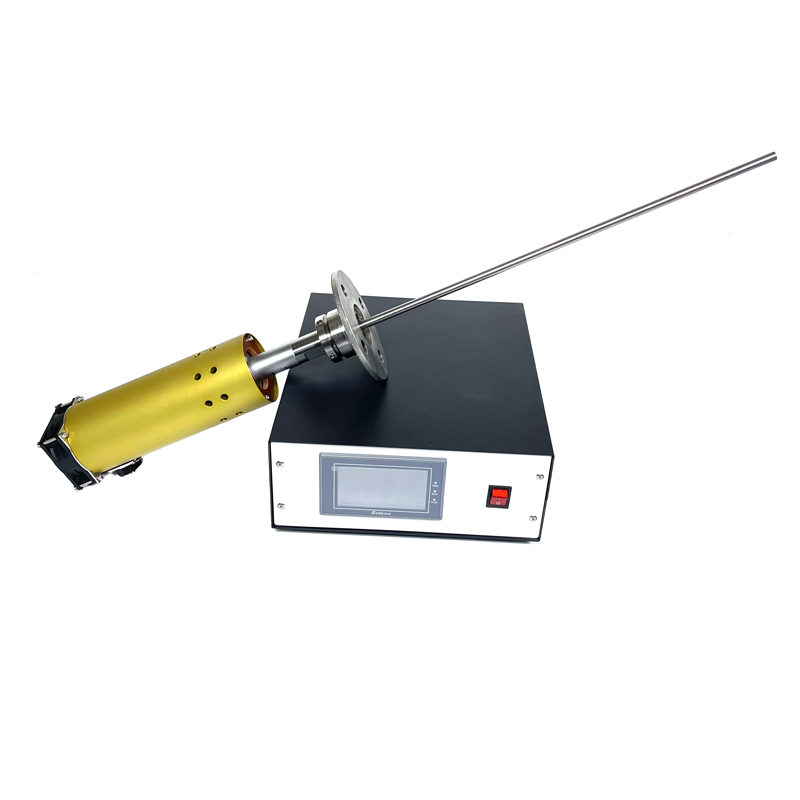

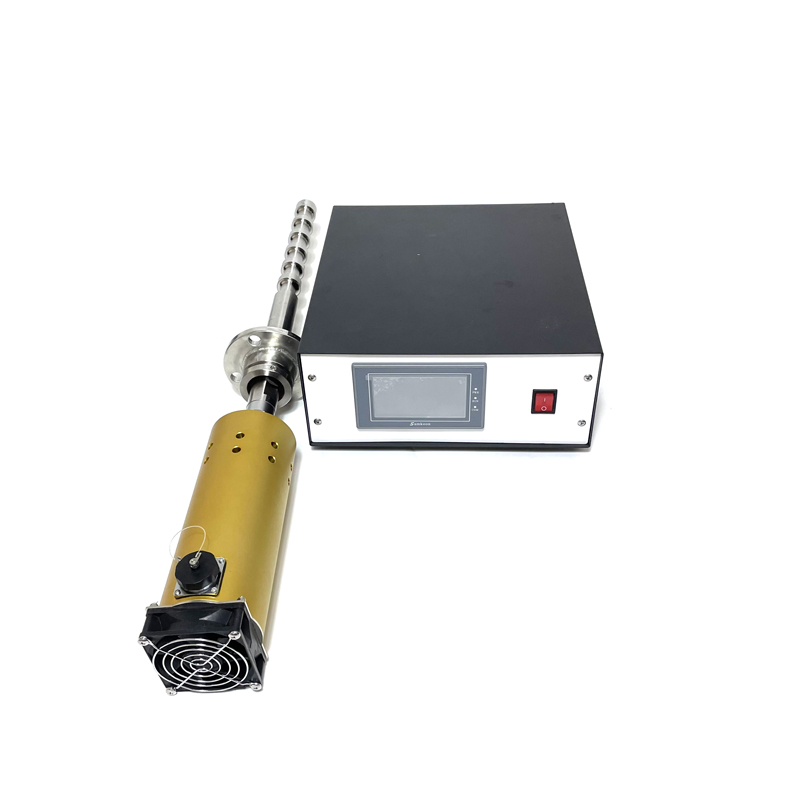

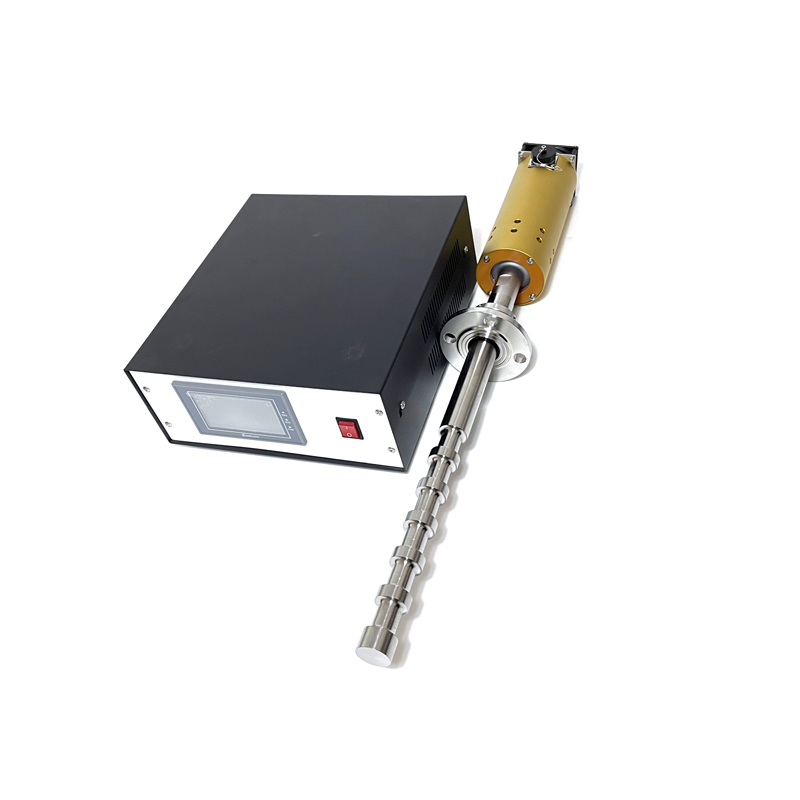

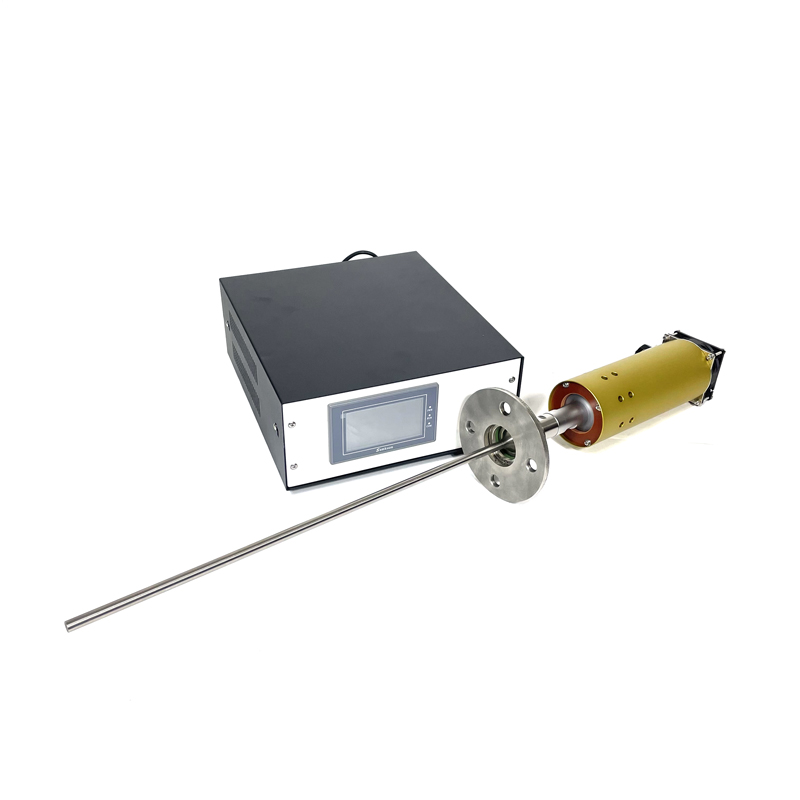

2000W Ultrasonic Biodiesel Reactor Liquid Ultrasonic Oil Extraction Machine

Microwave extraction technology Microwave extraction technology is also known as microwave assisted extraction (MAE). During extraction, when the microwave reaches the vascular bundle and gland cells inside the plant material through the solvent, the temperature in the cells suddenly rises, which makes the interna…

2000W Ultrasonic Biodiesel Reactor Liquid Ultrasonic Oil Extraction Machine

Microwave extraction technology

Microwave extraction technology is also known as microwave assisted extraction (MAE). During extraction, when the microwave reaches the vascular bundle and gland cells inside the plant material through the solvent, the temperature in the cells suddenly rises, which makes the internal pressure exceed the expansion capacity of the cell wall space, resulting in the cell wall rupture; The effective substances in the cells flow out freely and enter the extractant to be dissolved and then separated to achieve the purpose of extraction. The main control parameters of microwave extraction technology include extraction solvent, power density time, etc.

Application of microwave extraction technology at present

4.1 It is used for the extraction of bioactive components of natural products. At present, the microwave extraction technology has been studied for the extraction of flavonoids, saponins, volatile oils and other substances of natural products;

4.2 For the extraction of effective ingredients in food, microwave extraction technology can be used for the extraction of pigments, oils, polysaccharides, nutrients and flavor substances.

- Ultrasonic extraction technology

Ultrasonic extraction (UE for short), also known as ultrasonic-assisted extraction, is based on the principle of using the strong cavitation effect, disturbance effect, high acceleration, crushing and stirring effects generated by the ultrasonic radiation pressure to increase the frequency and speed of the movement of material molecules and increase the penetration of solvent, thus accelerating the target components into the solvent, promoting the extraction process and improving the extraction efficiency. The main control parameters of ultrasonic extraction technology include extraction solvent, ultrasonic frequency, time, etc. At present, the research of ultrasonic extraction is limited to single-frequency ultrasonic extraction technology, and the research of complex or dual-frequency ultrasonic extraction is still at the beginning stage.

- Ultra-high pressure extraction technology

Ultra-high pressure extraction technology (UPE) is also a new extraction technology. Its working principle is that the solvent enters the cell rapidly under the pressure rising state, filling the cell with solvent, and the effective components are fully dissolved in the solvent under the pressure maintaining state, and the solution dissolved in the effective components is released from the cell during the pressure relief, and then separated and purified to achieve the purpose of extraction. The ultra-high pressure extraction process is carried out in a closed system, without solvent volatilization, and is green and environmentally friendly.

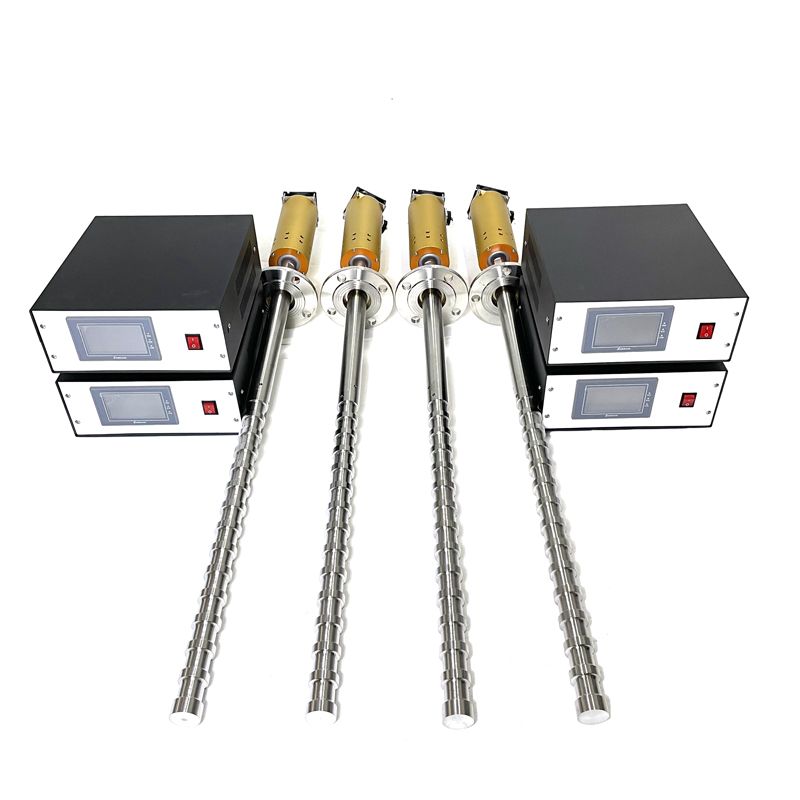

| Tubular EquipmentType | Tubular TransducerType | Frequency(KHz) | UltrasoundOutput(W) | Total Length(mm) | Diameter(mm) | Static Capacity(pF±10%) |

| PU-UE1 | US-61 | 15-28 | 1000 | 500 | Φ50-55 | 68000 |

| PU-UE5 | US-25 | 15-28 | 1500 | 850 | Φ50-55 | 68000 |

| PU-UE6 | US-16 | 15-28 | 2000 | 1100 | Φ50-55 | 132000 |

2000W Ultrasonic Biodiesel Reactor Liquid Ultrasonic Oil Extraction Machine

标签:2000W Ultrasonic Biodiesel Reactor, Ultrasonic Oil Extraction Machine

Send Inquiry

Laboratory Ultrasonic Emulsifier Homogenizer And Processor Mixer Disrupter Reactor With Ultrasonic Generator

Laboratory Ultrasonic Emulsifier Homogenizer And Processor Mixer Disrupter Reactor With Ultrasonic Generator Industrial Ultrasonic Homogenizer Ultrasonic Dispersion Emulsifier High Frequency Ultrasonic Probe Sonicator

Industrial Ultrasonic Homogenizer Ultrasonic Dispersion Emulsifier High Frequency Ultrasonic Probe Sonicator Ultrasonic Lab Homogenizer Herbal Extraction Machine Liquid Sonochemistry Processor Ultrasound Cell Disruption Equipment

Ultrasonic Lab Homogenizer Herbal Extraction Machine Liquid Sonochemistry Processor Ultrasound Cell Disruption Equipment Ultrasonic Emulsifying Dispersion 300W Ultrasonic Liquid Reactor Homogenizer With Generator

Ultrasonic Emulsifying Dispersion 300W Ultrasonic Liquid Reactor Homogenizer With Generator Ultrasonic Emulsification Disperser Cosmetic Mixing Extraction Ultrasonic Extraction Equipment

Ultrasonic Emulsification Disperser Cosmetic Mixing Extraction Ultrasonic Extraction Equipment Ultrasound & Microwave Reactor Ultrasonic And Microwave Combined Reaction System

Ultrasound & Microwave Reactor Ultrasonic And Microwave Combined Reaction System Laboratory Ultrasonic Liquid Processor Homogenizer Ultrasonic Homogenizer Machine Emulsifier

Laboratory Ultrasonic Liquid Processor Homogenizer Ultrasonic Homogenizer Machine Emulsifier Industrial Ultrasonic Extractor Dispersion Liquid Sonochemistry Reactor Laboratory Ultrasonic Emulsifier Equipment

Industrial Ultrasonic Extractor Dispersion Liquid Sonochemistry Reactor Laboratory Ultrasonic Emulsifier Equipment 20khz 1000W Industrial Ultrasonic Emulsifier Biodiesel Processor Reactor Sonochemistry Ultrasonic Biodiesel

20khz 1000W Industrial Ultrasonic Emulsifier Biodiesel Processor Reactor Sonochemistry Ultrasonic Biodiesel 2000W Ultrasound Reactor Biodiesel Ultrasonic Tube Assisted Synthesis Of Biodiesel With Wave Generator

2000W Ultrasound Reactor Biodiesel Ultrasonic Tube Assisted Synthesis Of Biodiesel With Wave Generator 20khz 2600W Industrial Ultrasonic Assisted Extraction Ultrasonic Dispersion With Wave Generator

20khz 2600W Industrial Ultrasonic Assisted Extraction Ultrasonic Dispersion With Wave Generator 3000W 20KHZ Ultrasonic Cavitation Reactor For Enhanced Microbial Biofuel Yields

3000W 20KHZ Ultrasonic Cavitation Reactor For Enhanced Microbial Biofuel Yields