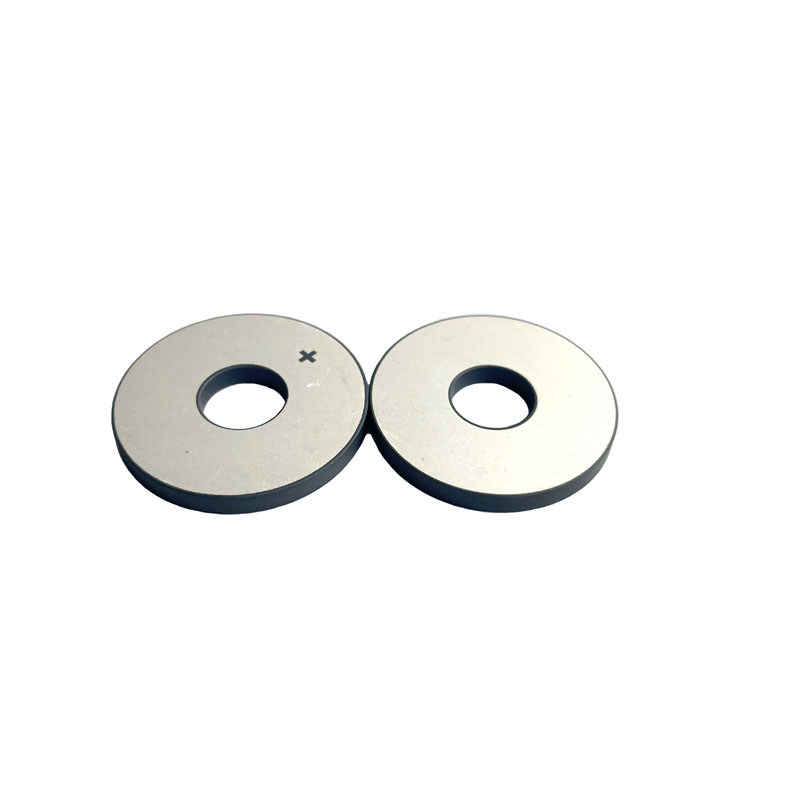

35*15*5mm Piezoelectric Ceramic Ring PZT Electronic Ceramic Piezoelectric Pressure Sensors

The preparation process of circular piezoelectric ceramic sheets mainly includes steps such as preparing ceramic raw materials, preparing piezoelectric ceramic green bodies, heat treatment, and polarization treatment. Any mistake in any of these steps may affect the performance of the final product. Therefore, the pr…

35*15*5mm Piezoelectric Ceramic Ring PZT Electronic Ceramic Piezoelectric Pressure Sensors

The preparation process of circular piezoelectric ceramic sheets mainly includes steps such as preparing ceramic raw materials, preparing piezoelectric ceramic green bodies, heat treatment, and polarization treatment. Any mistake in any of these steps may affect the performance of the final product. Therefore, the preparation of circular piezoelectric ceramic sheets requires strict control of each process step to ensure the performance and quality of the final product.

The performance of circular piezoelectric ceramic sheets mainly includes parameters such as piezoelectric constant, electromechanical coupling coefficient, mechanical quality factor, and dielectric constant. These parameters directly affect the application range and effectiveness of circular piezoelectric ceramic sheets. Therefore, when selecting and using circular piezoelectric ceramic sheets, it is necessary to choose the appropriate model and specification according to actual needs.

| spec | Dimension (mm) | Radial frequency (KHz) | Capacitance (pf) | Dielectric dissipation factor tanδ(%) | Electromechanical coupling coefficient (Kr) | Impedance Zr(Ω) | Thickness frequency (KHz) |

| PU-PC25103 | Φ25×Φ10×3 | 66.4 | 1240±12.5% | ≤0.3 | ≥0.46 | ≤15 | 683±5% |

| PU-PC225104 | Φ25×Φ10×4 | 66.4 | 930±12.5% | ≤0.3 | ≥0.46 | ≤15 | 512±5% |

| PU-PC40155 | Φ40×Φ12×5 | 45.9 | 2070±12.5% | ≤0.3 | ≥0.46 | ≤15 | 410±5% |

| PU-PC40155 | Φ40×Φ15×5 | 42.2 | 1960±12.5% | ≤0.3 | ≥0.46 | ≤15 | 323±5% |

| PU-PC40176 | Φ40×Φ17×6 | 40.5 | 1555±12.5% | ≤0.3 | ≥0.46 | ≤15 | 341±5% |

| PU-PC40205 | Φ40×Φ20×5 | 37.9 | 1700±12.5% | ≤0.3 | ≥0.47 | ≤15 | 410±5% |

| PU-PC50206 | Φ50×Φ20×6 | 33.2 | 2490±12.5% | ≤0.3 | ≥0.46 | ≤15 | 341±5% |

| PU-PC501765 | Φ50×Φ17×6.5 | 34.8 | 2430±12.5% | ≤0.3 | ≥0.46 | ≤15 | 315±5% |

| PU-PC50236 | Φ50×Φ23×6 | 31.2 | 2340±12.5% | ≤0.3 | ≥0.47 | ≤15 | 341±5% |

| PU-PC50276 | Φ50×Φ27×6 | 29.3 | 2100±12.5% | ≤0.3 | ≥0.47 | ≤15 | 341±5% |

| PU-PC603010 | Φ60×Φ30×10 | 25.3 | 1922±12.5% | ≤0.3 | ≥0.47 | ≤18 | 205±5% |

35*15*5mm Piezoelectric Ceramic Ring PZT Electronic Ceramic Piezoelectric Pressure Sensors

标签:Ceramic Piezoelectric Pressure Sensors, Piezoelectric Ceramic Ring PZT Electronic

Send Inquiry

Piezoelectric ceramic plate for Ultrasonic pzt material D20*2mm PZT5 Ultrasonic bubble detection

Piezoelectric ceramic plate for Ultrasonic pzt material D20*2mm PZT5 Ultrasonic bubble detection 38.1*12.75*6.35mm Piezoelectric Ceramic Ring For 100W 28khz Ultrasonic Washing Machine Transducer

38.1*12.75*6.35mm Piezoelectric Ceramic Ring For 100W 28khz Ultrasonic Washing Machine Transducer PZT4 PZT5 PZT8 Customization 40mm Ultrasonic Piezo Transducer Ceramic Element Piezoelectric Sensor

PZT4 PZT5 PZT8 Customization 40mm Ultrasonic Piezo Transducer Ceramic Element Piezoelectric Sensor 10x5x2mm PZT-8/PZT-4 Piezoelectric Ceramic Ring For 33khz 50W Medical Teeth Cleaning Ultrasonic Transducer

10x5x2mm PZT-8/PZT-4 Piezoelectric Ceramic Ring For 33khz 50W Medical Teeth Cleaning Ultrasonic Transducer 38.1*15*5mm Ring Piezoelectric Ceramic PZT Material Piezoceramic Ring Manufacturers And Company

38.1*15*5mm Ring Piezoelectric Ceramic PZT Material Piezoceramic Ring Manufacturers And Company 38.1*12.75*6.35mm Pzt4 Material Ultrasonic Ceramic Piezo Element For Ultrasonic Sensor

38.1*12.75*6.35mm Pzt4 Material Ultrasonic Ceramic Piezo Element For Ultrasonic Sensor Piezoelectric Ceramic Material PZT4 PZT5 PZT8 Tube Disc Ring Piezo Ceramic

Piezoelectric Ceramic Material PZT4 PZT5 PZT8 Tube Disc Ring Piezo Ceramic 28k/40k Round Type Piezoelectric Ceramic PZT4 Material As Ultrasound Transducer Component

28k/40k Round Type Piezoelectric Ceramic PZT4 Material As Ultrasound Transducer Component Piezo Vibration Piezoelectric Ceramic Transducer Ultrasonic Piezo Ring 40*20*5mm

Piezo Vibration Piezoelectric Ceramic Transducer Ultrasonic Piezo Ring 40*20*5mm 45*15*5mm PZT-8/PZT-4 Piezoelectric Ceramic Ring 28khz/35khz 800W Ultrasonic Welding Transducer With Booster

45*15*5mm PZT-8/PZT-4 Piezoelectric Ceramic Ring 28khz/35khz 800W Ultrasonic Welding Transducer With Booster Piezo Ring 50*17*6.5mm Piezoelectric Ceramic Element Customized Ultrasonic Piezoelectric Ceramic Ring

Piezo Ring 50*17*6.5mm Piezoelectric Ceramic Element Customized Ultrasonic Piezoelectric Ceramic Ring Piezoelectric Ceramic Element Piezo Ceramic Ultrasonic Transducer Ring For Piezo Phaco Handpiece

Piezoelectric Ceramic Element Piezo Ceramic Ultrasonic Transducer Ring For Piezo Phaco Handpiece