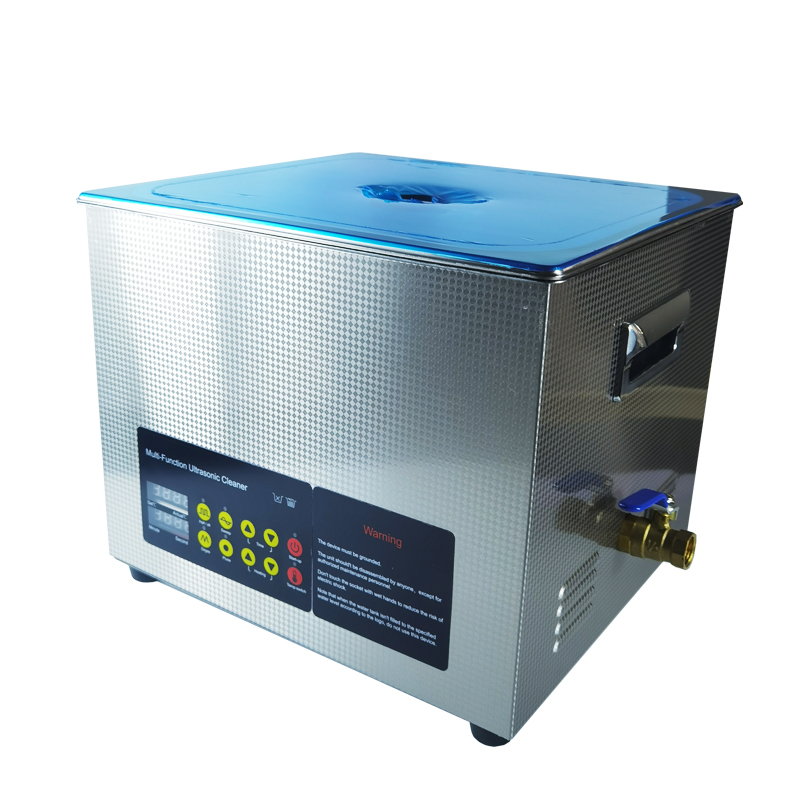

6.5L 180W Digital Industrial Ultrasonic Stainless Steel Tank For Engine Parts And Circuit Board Cleaner

Ultrasonic cleaning machine cleaning process flow: Add tap water to the cleaning tank, ensuring that the water level is higher than or equal to 3/4 of the height of the tank. Start electric heating and also start ultrasonic for degassing. When the water temperature is around 40 degrees Celsius, add the specified a…

Ultrasonic cleaning machine cleaning process flow:

- Add tap water to the cleaning tank, ensuring that the water level is higher than or equal to 3/4 of the height of the tank. Start electric heating and also start ultrasonic for degassing. When the water temperature is around 40 degrees Celsius, add the specified amount of ultrasonic special cleaning agent. When the water temperature reaches 55-60 degrees Celsius, start cleaning the parts.

- Disassemble the parts that need to be cleaned as much as possible, and use high-pressure water guns, wire brushes, shovels, or other tools to manually assist in pre-treatment of the soil, heavy oil stains, and heavy carbon deposits on the surface of the parts to ensure the service life of the cleaning solution and the speed and effectiveness of cleaning.

- Place the parts that need to be cleaned into the cleaning pool, without overlapping, to ensure that the parts are submerged by the cleaning solution.

- Start the ultrasonic wave and clean it regularly for 20-30 minutes. After cleaning, turn off the ultrasonic wave and remove the components for post-processing.

- Use a high-pressure water gun to remove the residue on the surface of the components, and use an air compression gun to remove the residue in the pores. Parts that require rust prevention will be treated separately. To improve the cleaning effect, if time permits,

The cleaning time of components in the cleaning solution can be appropriately extended. In actual operation, in order to improve cleaning efficiency, a process flow of disassembly and cleaning can be adopted.

| Type | Capacity | Power | Fre | heating | Tank size | Overall size | Package size | Net weight | Gross weight | drainage |

| * | L | W | KHZ | W | (LⅹwⅹH)mm | (LⅹwⅹH)mm | (LⅹwⅹH)mm | KG | KG | yes/no |

| PLS-MD1LH | 1.3L | 60 | 40 | 150 | 150*135*65 | 175*160*210 | 260*250*265 | 2.3 | 2.8 | / |

| PLS-MD1LH-1 | 1.3L | 120 | 40 | 150 | 150*135*65 | 175*160*210 | 260*250*265 | 2.8 | 3.5 | / |

| PLS-MD2LH | 2L | 60 | 40 | 150 | 150*135*100 | 175*160*220 | 260*250*310 | 2.3 | 2.8 | / |

| PLS-MD2LH-1 | 2L | 120 | 40 | 150 | 150*135*100 | 175*160*220 | 260*250*310 | 2.3 | 2.8 | / |

| PLS-MD3LH | 3.2L | 120 | 40 | 150 | 240*135*100 | 265*165*220 | 340*245*310 | 3.5 | 4.1 | / |

| PLS-MD3LH-1 | 3.2L | 180 | 40 | 150 | 240*135*100 | 265*165*220 | 340*245*310 | 4 | 4.6 | / |

| PLS-MD4LH | 4.5L | 180 | 40 | 300 | 300*150*100 | 325*180*225 | 410*255*310 | 4.5 | 5.6 | / |

| PLS-MD6LH | 6.5L | 180 | 40 | 300 | 300*150*150 | 325*180*308 | 410*255*375 | 5.5 | 6.4 | yes |

| PLS-MD10LH | 10L | 240 | 40 | 450 | 300*240*150 | 325*265*308 | 435*360*375 | 7.4 | 8.5 | yes |

| PLS-MD10LH-1 | 10L | 360 | 40 | 450 | 300*240*150 | 325*265*308 | 435*360*375 | 8.4 | 9.5 | yes |

| PLS-MD15LH | 15L | 360 | 40 | 450 | 330*300*150 | 360*325*308 | 460*410*375 | 9 | 10.5 | yes |

| PLS-MD15LH-1 | 15L | 480 | 40 | 450 | 330*300*150 | 360*325*308 | 460*410*375 | 10 | 12 | yes |

| PLS-MD15LH-2 | 15L | 540 | 40 | 450 | 330*300*150 | 360*325*308 | 460*410*375 | 11 | 13 | yes |

| PLS-MD22LH | 22L | 480 | 40 | 600 | 500*300*150 | 530*325*308 | 635*405*380 | 12.1 | 13.7 | yes |

| PLS-MD22LH-1 | 22L | 600 | 40 | 600 | 500*300*150 | 530*325*308 | 635*405*380 | 13.1 | 14.7 | yes |

| PLS-MD22LH-2 | 22L | 720 | 40 | 600 | 500*300*150 | 530*325*308 | 635*405*380 | 14.1 | 15.7 | yes |

| PLS-MD22LH-3 | 22L | 840 | 40 | 600 | 500*300*150 | 530*325*308 | 635*405*380 | 15.1 | 16.7 | yes |

| PLS-MD22LH-4 | 22L | 900 | 40 | 600 | 500*300*150 | 530*325*308 | 635*405*380 | 15.6 | 17.2 | yes |

| PLS-MD30LH | 30L | 600 | 40 | 600 | 500*300*200 | 530*325*354 | 635*405*420 | 14 | 15.6 | yes |

| PLS-MD30LH-1 | 30L | 720 | 40 | 600 | 500*300*200 | 530*325*354 | 635*405*420 | 15 | 17 | yes |

| PLS-MD30LH-2 | 30L | 840 | 40 | 600 | 500*300*200 | 530*325*354 | 635*405*420 | 17 | 19 | yes |

| PLS-MD30LH-3 | 30L | 900 | 40 | 600 | 500*300*200 | 530*325*354 | 635*405*420 | 17.5 | 19.5 | yes |

标签:6.5L 180W Digital Industrial Ultrasonic Stainless Steel Tank, Digital Industrial Ultrasonic Stainless Steel Tank, Ultrasonic Stainless Steel Tank For Engine Parts And Circuit Board Cleaner

Send Inquiry

Ultrasonic Cleaner For Jewelry Watch Ring Coin Diamond Eyeglasses Small Parts Cleaning 4.5l Ultrasonic Cleaner

Ultrasonic Cleaner For Jewelry Watch Ring Coin Diamond Eyeglasses Small Parts Cleaning 4.5l Ultrasonic Cleaner Single Large Tank 500W Heated Industrial Ultrasonic Cleaner for Lab Auto Parts Plant Repairing

Single Large Tank 500W Heated Industrial Ultrasonic Cleaner for Lab Auto Parts Plant Repairing Small Household Ultrasonic Jewelry Cleaner Glasses Other Dental Equipments Ultrasonic Washer Cleaners

Small Household Ultrasonic Jewelry Cleaner Glasses Other Dental Equipments Ultrasonic Washer Cleaners 150W 40KHZ Pulse Ultrasonic Cleaner With Filtration Portable Ultrasonic Cleaning Machine

150W 40KHZ Pulse Ultrasonic Cleaner With Filtration Portable Ultrasonic Cleaning Machine 20L Industrial Dpf Digital Ultrasonic Cleaning Machine For Engine Parts Cleaning Tank

20L Industrial Dpf Digital Ultrasonic Cleaning Machine For Engine Parts Cleaning Tank 6L Portable High Frequency Cleaning Machine Digital Dental Denture Watch Glasses Jewelry Ultrasonic Cleaners

6L Portable High Frequency Cleaning Machine Digital Dental Denture Watch Glasses Jewelry Ultrasonic Cleaners Industry Digital Ultrasonic Cleaner Heater 2l Timer Stainless Digital Ultrasonic Cleaners Cleaning Equipment

Industry Digital Ultrasonic Cleaner Heater 2l Timer Stainless Digital Ultrasonic Cleaners Cleaning Equipment 3l Stainless Steel Ultrasonic Cleaner With Digital Lcd Display For Watch Jewelry Or Pcb Brush Ultrasonic Printhead Cleaner

3l Stainless Steel Ultrasonic Cleaner With Digital Lcd Display For Watch Jewelry Or Pcb Brush Ultrasonic Printhead Cleaner Digital Timer Display Jewelry Eyeglasses Tank Equipment Rusty Tool Cleaning Ultrasonic Cleaners For Car Parts

Digital Timer Display Jewelry Eyeglasses Tank Equipment Rusty Tool Cleaning Ultrasonic Cleaners For Car Parts 6L 180W Digital Ultrasonic Cleaner Engine Machinery Repair Shops Restaurant Metal

6L 180W Digital Ultrasonic Cleaner Engine Machinery Repair Shops Restaurant Metal 50W Multifunction Ultrasonic Cleaner With Degas Sweep Heated For Cions Watch And Jewellery Ultrasonic Cleaner

50W Multifunction Ultrasonic Cleaner With Degas Sweep Heated For Cions Watch And Jewellery Ultrasonic Cleaner Digital Mini Ultrasonic Cleaner Jewelry Stainless Steel Tank 6.5L Commercial Ultrasonic Cleaner Machine

Digital Mini Ultrasonic Cleaner Jewelry Stainless Steel Tank 6.5L Commercial Ultrasonic Cleaner Machine