88l Industrial Ultrasonic Cleaner With Cycle Filtration Cleaning And Drying Functions

Maintenance of Ultrasonic Cleaning Machine Please cut off the power supply when not in use and keep the machine clean.Please keep away from heat source. The machine may be damaged by electronic components and circuits under high temperature.After using the ultrasonic cleaner, please discharge the solution complete…

88l Industrial Ultrasonic Cleaner With Cycle Filtration Cleaning And Drying Functions

Maintenance of Ultrasonic Cleaning Machine

- Please cut off the power supply when not in use and keep the machine clean.

- Please keep away from heat source. The machine may be damaged by electronic components and circuits under high temperature.

- After using the ultrasonic cleaner, please discharge the solution completely, do a good job of dust prevention and moisture-proof, and avoid storing the machine in a damp environment.

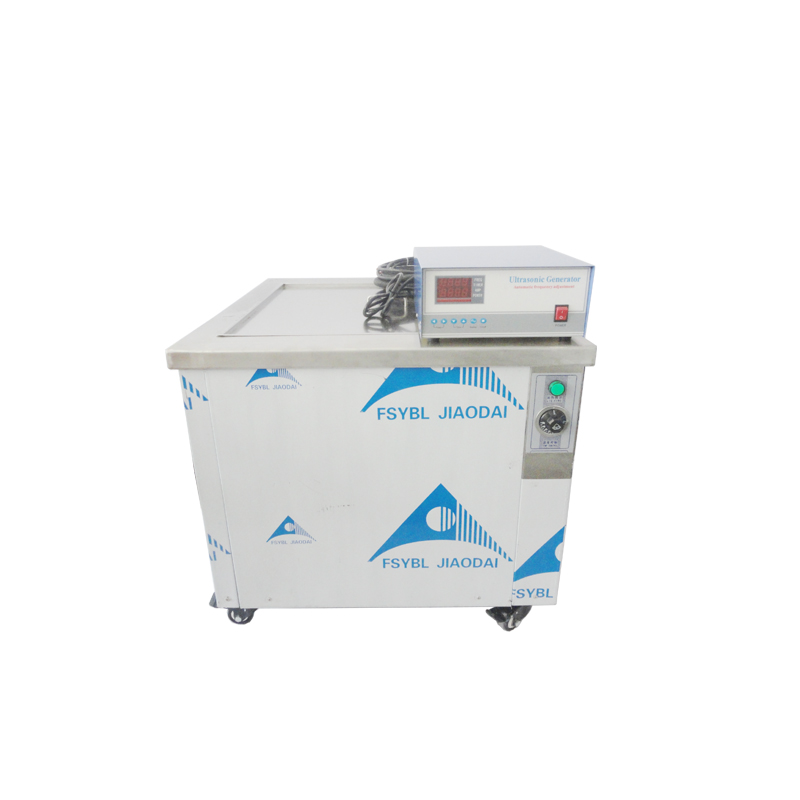

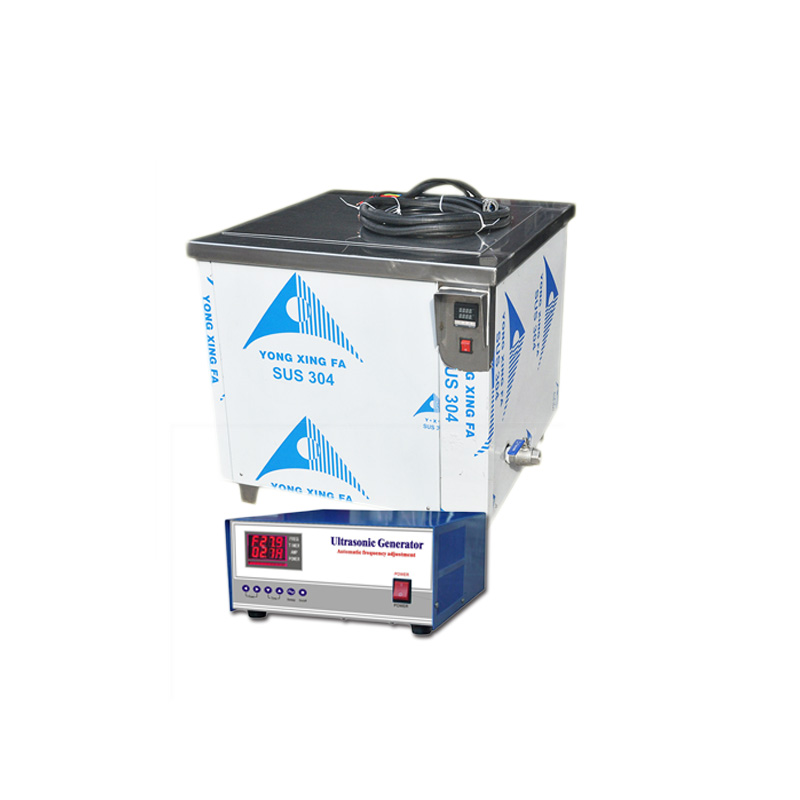

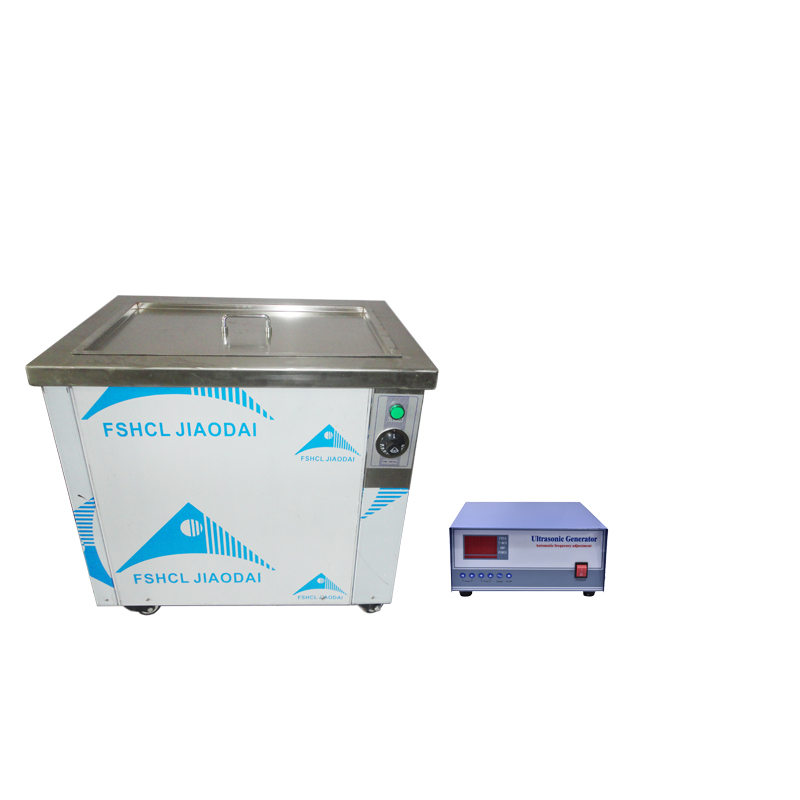

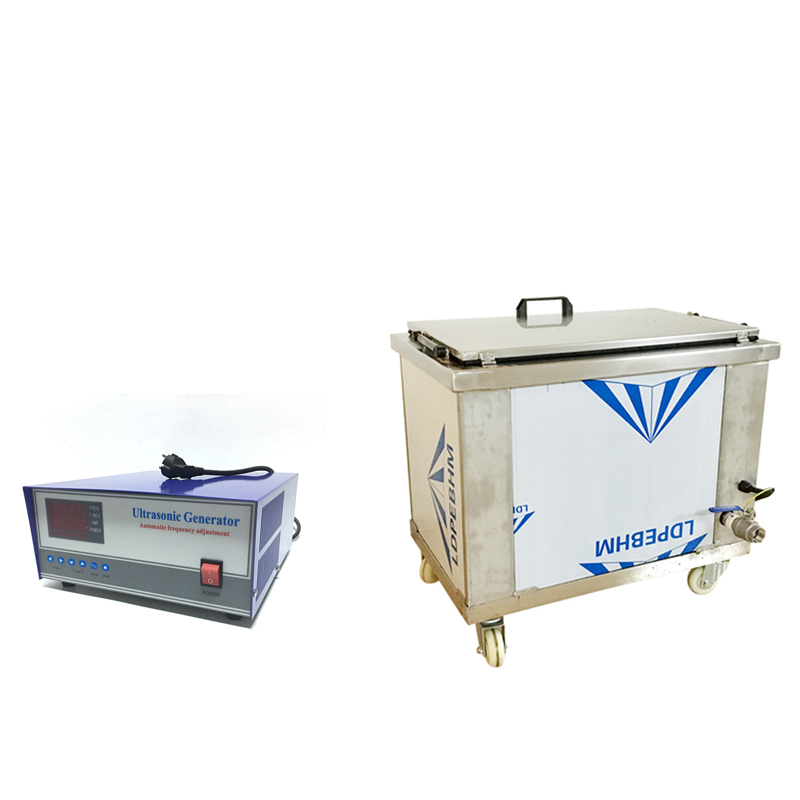

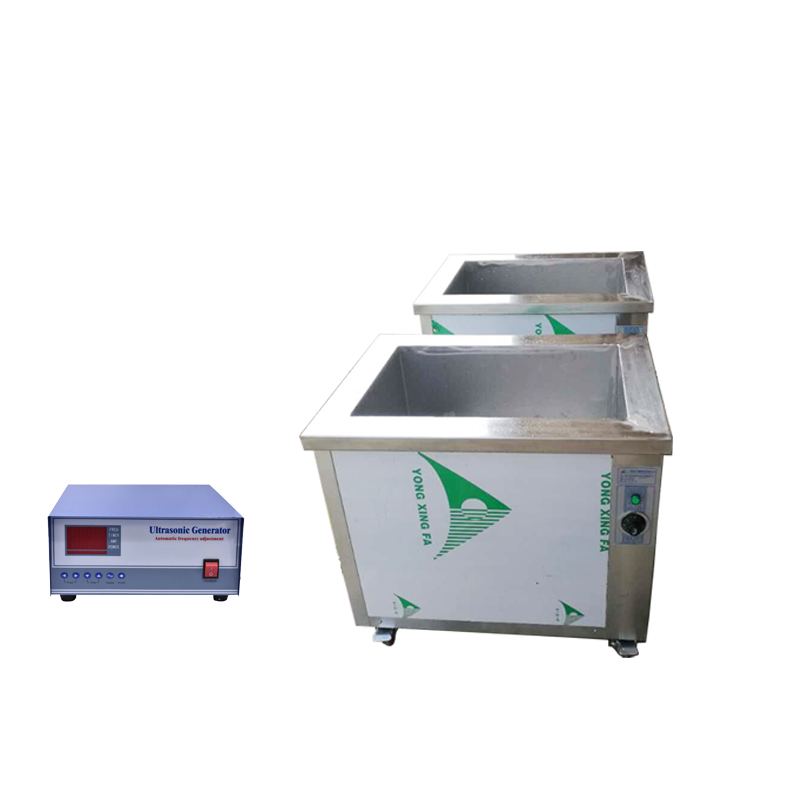

The single tank ultrasonic cleaning machine is composed of an electronic control box and an ultrasonic cleaning tank. It has good cleaning stability, few failures and strong output. This is why the single tank ultrasonic cleaning machine is a mechanical wave whose vibration frequency can be higher than the sound wave, which can generate the vibration of the energy conversion chip under the excitation of voltage. This machine uses water base and a little additive as cleaning agent, which has low cost and good cleaning effect. Scope of application: cleaning of electronic parts, electroplating, hardware, clocks, watchbands, tools, optical lenses, jewelry, lenses, spectacle frames, half channel silicon chips, spinneret filter elements and glassware.

| Type | Internal size L*W*H (mm) | Frequency (Khz) | Power(W) | Heating(W) |

| PU-1006TT | 280×210×210 | 20,28,33,40,80,130 | 300 | 1000 |

| PU-1012TT | 400×310×280 | 20,28,33,40,80,130 | 600 | 3000 |

| PU-1018TT | 490×360×320 | 20,28,33,40,80,130 | 900 | 3000 |

| PU-1024TT | 630×430×320 | 20,28,33,40,80,130 | 1200 | 4000 |

| PU-1030TT | 630×530×320 | 20,28,33,40,80,130 | 1500 | 4000 |

| PU-1036TT | 680×530×360 | 20,28,33,40,80,130 | 1800 | 5000 |

| PU-1040TT | 680×570×400 | 20,28,33,40,80,130 | 2000 | 5000 |

| PU-1041TT | 730×570×450 | 20,28,33,40,80,130 | 2400 | 6000 |

| PU-1042TT | 790×670×510 | 20,28,33,40,80,130 | 3000 | 6000 |

| PU-1043TT | 850×770×570 | 20,28,33,40,80,130 | 4000 | 7000 |

| PU-1044ST | 910×820×620 | 20,28,33,40,80,130 | 5000 | 7000 |

| PU-1045TT | 960×870×680 | 20,28,33,40,80,130 | 8000 | 8000 |

| PU-1046TT | 1100×930×730 | 20,28,33,40,80,130 | 10000 | 8000 |

88l Industrial Ultrasonic Cleaner With Cycle Filtration Cleaning And Drying Functions

标签:Industrial Ultrasonic Cleaner, single tank ultrasonic cleaning machine, Ultrasonic Cleaning Machine

Send Inquiry

High Power Digital Industrial Ultrasonic Cleaner 80L 40L For Glass Bottle Cleaner System

High Power Digital Industrial Ultrasonic Cleaner 80L 40L For Glass Bottle Cleaner System Industry Sweeping Frequency Degas Ultrasonic Cleaner Automatic Metal Mould Parts Dirty Remove Ultrasound Bath 28KHZ Optional

Industry Sweeping Frequency Degas Ultrasonic Cleaner Automatic Metal Mould Parts Dirty Remove Ultrasound Bath 28KHZ Optional Power Adjustable Ultrasonic Cleaner Machine And Ultrasonic Cleaning Generator For Industrial Parts

Power Adjustable Ultrasonic Cleaner Machine And Ultrasonic Cleaning Generator For Industrial Parts 28khz Industrial Engine Block Ultrasonic Cleaner Ultrasonic Cleaning Washing Machine And Power Generator

28khz Industrial Engine Block Ultrasonic Cleaner Ultrasonic Cleaning Washing Machine And Power Generator Custom Engineered Ultrasonic Cleaning Systems 2400W 28KHZ China Customized Single Tank Ultrasonic Cleaner Suppliers

Custom Engineered Ultrasonic Cleaning Systems 2400W 28KHZ China Customized Single Tank Ultrasonic Cleaner Suppliers 28KHZ 2400W Large Industrial Ultrasonic Parts Cleaner Building DIY Ultrasonic Cleaner Ultrasonic Cleaner Machine

28KHZ 2400W Large Industrial Ultrasonic Parts Cleaner Building DIY Ultrasonic Cleaner Ultrasonic Cleaner Machine Single Tank Cleaning Engine Industrial Ultrasonic Cleaner Ultrasonic Cleaner Bath Tank Laboratory Small Ultrasonic Cleaner

Single Tank Cleaning Engine Industrial Ultrasonic Cleaner Ultrasonic Cleaner Bath Tank Laboratory Small Ultrasonic Cleaner Multifunctional Sweep Frequency Lab Sonic Cleaner Pulse Degass Ultrasonic Bath Cleaner 40KHZ Ultrasonic Cleaning Machine

Multifunctional Sweep Frequency Lab Sonic Cleaner Pulse Degass Ultrasonic Bath Cleaner 40KHZ Ultrasonic Cleaning Machine Multifunctional Ultrasonic Cleaner Degas Sweep Frequency Large Capacity 1000W Industrial Digital Ultrasonic Cleaning Machine

Multifunctional Ultrasonic Cleaner Degas Sweep Frequency Large Capacity 1000W Industrial Digital Ultrasonic Cleaning Machine Single Tank Industrial Ultrasonic Washer Machine Cleaner Fuel Tank Carwheel Cleaning Carburetor Parts Cleaner

Single Tank Industrial Ultrasonic Washer Machine Cleaner Fuel Tank Carwheel Cleaning Carburetor Parts Cleaner 2500W 40KHZ Large Capacity Industrial Ultrasonic Washing Machine With Frequency Generator

2500W 40KHZ Large Capacity Industrial Ultrasonic Washing Machine With Frequency Generator 1000W 40KHZ Industrial Digital Power Adjustable Ultrasonic Cleaner Machine With Ultrasonic Generator

1000W 40KHZ Industrial Digital Power Adjustable Ultrasonic Cleaner Machine With Ultrasonic Generator