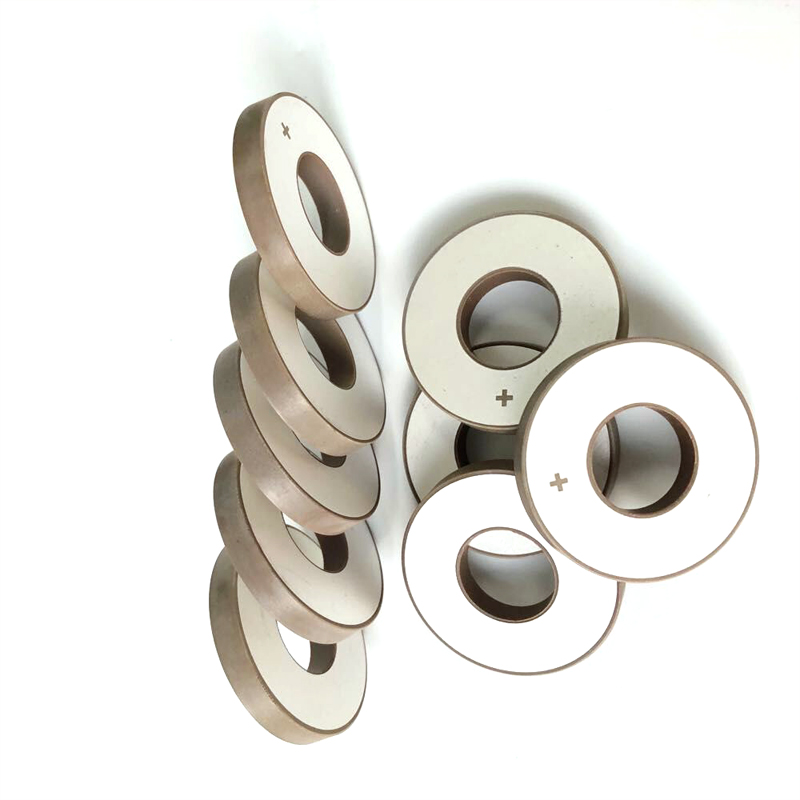

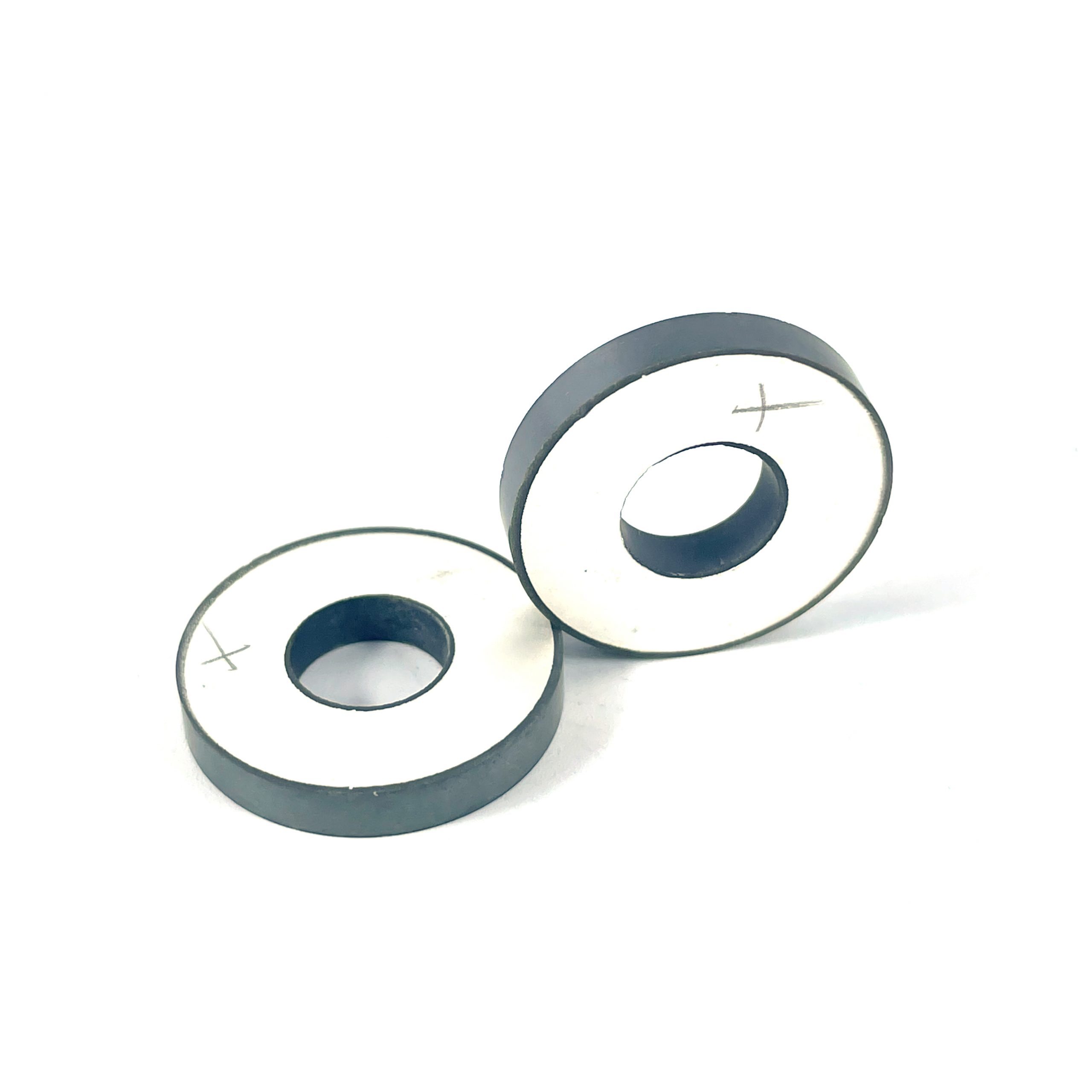

Industrial 50*20*5mm Piezoelectric Ceramic Element Welding Transducer Piezo Ceramic Piezoelectric Ceramic

The basic characteristic of piezoelectric ceramic sheets is that they have a “piezoelectric effect”, that is, when subjected to external pressure from the vertical direction, as the sheet bends and deforms (changes in geometry), a voltage is generated on both electrode surfaces, and the magnitude of the v…

The basic characteristic of piezoelectric ceramic sheets is that they have a “piezoelectric effect”, that is, when subjected to external pressure from the vertical direction, as the sheet bends and deforms (changes in geometry), a voltage is generated on both electrode surfaces, and the magnitude of the voltage is proportional to the change in pressure. By utilizing this feature, piezoelectric ceramic sheets can be used as sensors for pressure changes (or vibration waves), and electronic circuits can be used to monitor the instantaneous changes in force conditions at a certain location, which is very useful in practice. On the contrary, if a direct current voltage is applied to the two electrode surfaces of a piezoelectric ceramic sheet, the sheet will undergo corresponding mechanical deformation (i.e., the “reverse piezoelectric effect”).

| spec | Dimension (mm) | Radial frequency (KHz) | Capacitance (pf) | Dielectric dissipation factor tanδ(%) | Electromechanical coupling coefficient (Kr) | Impedance Zr(Ω) | Thickness frequency (KHz) |

| PU-PC25103 | Φ25×Φ10×3 | 66.4 | 1240±12.5% | ≤0.3 | ≥0.46 | ≤15 | 683±5% |

| PU-PC225104 | Φ25×Φ10×4 | 66.4 | 930±12.5% | ≤0.3 | ≥0.46 | ≤15 | 512±5% |

| PU-PC40155 | Φ40×Φ12×5 | 45.9 | 2070±12.5% | ≤0.3 | ≥0.46 | ≤15 | 410±5% |

| PU-PC40155 | Φ40×Φ15×5 | 42.2 | 1960±12.5% | ≤0.3 | ≥0.46 | ≤15 | 323±5% |

| PU-PC40176 | Φ40×Φ17×6 | 40.5 | 1555±12.5% | ≤0.3 | ≥0.46 | ≤15 | 341±5% |

| PU-PC40205 | Φ40×Φ20×5 | 37.9 | 1700±12.5% | ≤0.3 | ≥0.47 | ≤15 | 410±5% |

| PU-PC50206 | Φ50×Φ20×6 | 33.2 | 2490±12.5% | ≤0.3 | ≥0.46 | ≤15 | 341±5% |

| PU-PC501765 | Φ50×Φ17×6.5 | 34.8 | 2430±12.5% | ≤0.3 | ≥0.46 | ≤15 | 315±5% |

| PU-PC50236 | Φ50×Φ23×6 | 31.2 | 2340±12.5% | ≤0.3 | ≥0.47 | ≤15 | 341±5% |

| PU-PC50276 | Φ50×Φ27×6 | 29.3 | 2100±12.5% | ≤0.3 | ≥0.47 | ≤15 | 341±5% |

| PU-PC603010 | Φ60×Φ30×10 | 25.3 | 1922±12.5% | ≤0.3 | ≥0.47 | ≤18 | 205±5% |

标签:Industrial 50*20*5mm Piezoelectric Ceramic, Piezoelectric Ceramic Element Welding Transducer

Send Inquiry

50*17*5mm PZT-8 Piezoelectric Ceramic Ring Ultrasonic Welder Machine Parts For 2000W Ultrasonic Welding Transducer

50*17*5mm PZT-8 Piezoelectric Ceramic Ring Ultrasonic Welder Machine Parts For 2000W Ultrasonic Welding Transducer 45*15*5mm PZT-8/PZT-4 Piezoelectric Ceramic Ring 28khz/35khz 800W Ultrasonic Welding Transducer With Booster

45*15*5mm PZT-8/PZT-4 Piezoelectric Ceramic Ring 28khz/35khz 800W Ultrasonic Welding Transducer With Booster PZT-8 PZT-4 Material Piezoelectric Ceramic Ring/Disc/Sheet for Ultrasonic Transducer

PZT-8 PZT-4 Material Piezoelectric Ceramic Ring/Disc/Sheet for Ultrasonic Transducer 10x5x2mm PZT-8/PZT-4 Piezoelectric Ceramic Ring For 33khz 50W Medical Teeth Cleaning Ultrasonic Transducer

10x5x2mm PZT-8/PZT-4 Piezoelectric Ceramic Ring For 33khz 50W Medical Teeth Cleaning Ultrasonic Transducer Piezo Ring 50*17*6.5mm Piezoelectric Ceramic Element Customized Ultrasonic Piezoelectric Ceramic Ring

Piezo Ring 50*17*6.5mm Piezoelectric Ceramic Element Customized Ultrasonic Piezoelectric Ceramic Ring 38*15*5mm Ring Ultrasonic Piezo Crystal Piezo Ceramic Ultrasonic Transducers Customization Ultrasonic Piezo Transducer

38*15*5mm Ring Ultrasonic Piezo Crystal Piezo Ceramic Ultrasonic Transducers Customization Ultrasonic Piezo Transducer PZT-8 PZT-4 Material Piezoelectric Ceramic Ring/Disc/Sheet for Ultrasonic Transducer

PZT-8 PZT-4 Material Piezoelectric Ceramic Ring/Disc/Sheet for Ultrasonic Transducer 35*15*5mm PZT-8/PZT-4 Piezoelectric Ceramic Ring For 50W 28khz/40khz Ultrasonic Cleaning Machine Transducer

35*15*5mm PZT-8/PZT-4 Piezoelectric Ceramic Ring For 50W 28khz/40khz Ultrasonic Cleaning Machine Transducer 38*15*5mm P81 Ultrasonic Piezo Element Piezoelectric Ceramic Ring For Ultrasonic Piezo Transducer

38*15*5mm P81 Ultrasonic Piezo Element Piezoelectric Ceramic Ring For Ultrasonic Piezo Transducer Piezoelectric ceramic plate for Ultrasonic pzt material D20*2mm PZT5 Ultrasonic bubble detection

Piezoelectric ceramic plate for Ultrasonic pzt material D20*2mm PZT5 Ultrasonic bubble detection 10×5*x2mm PZT8 Piezo Ceramic for Tooth Cleaning Ultrasonic Beauty Transducer

10×5*x2mm PZT8 Piezo Ceramic for Tooth Cleaning Ultrasonic Beauty Transducer Piezoelectric Ceramic Crystals Piezo Element 50*20*6.5mm for ultrasonic welding machine

Piezoelectric Ceramic Crystals Piezo Element 50*20*6.5mm for ultrasonic welding machine