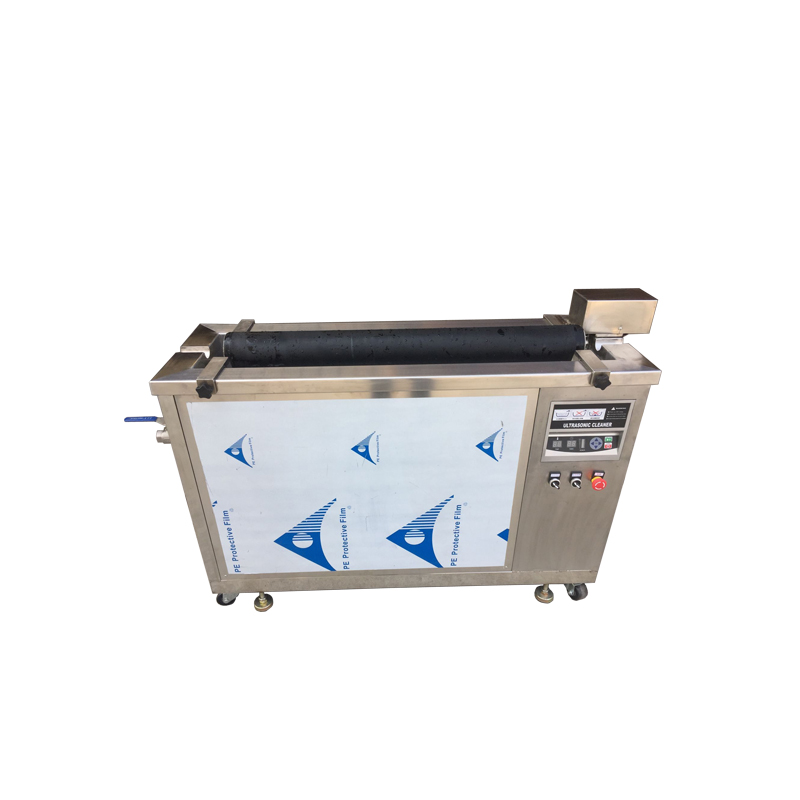

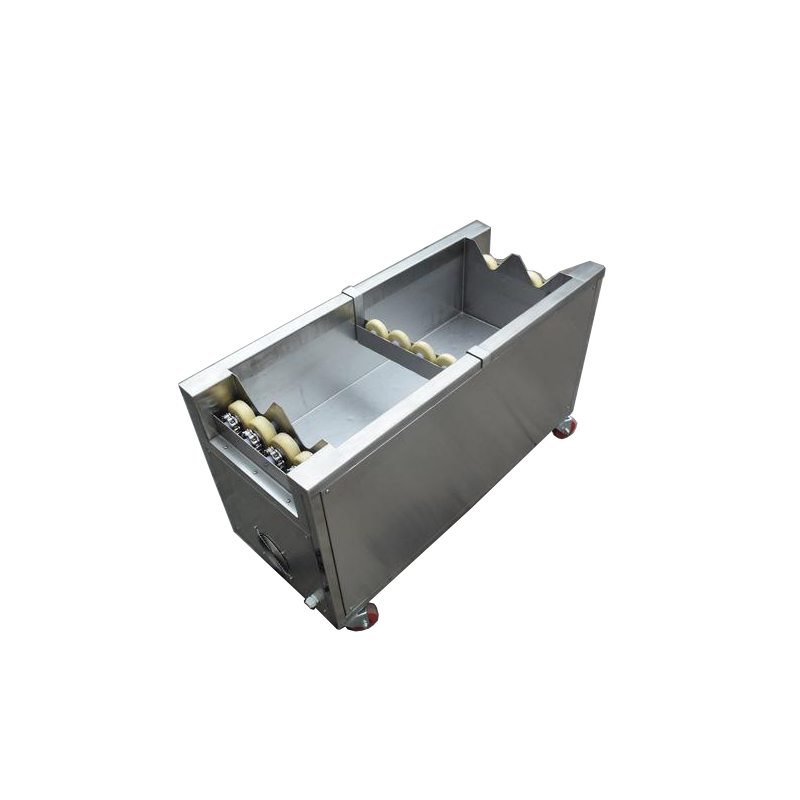

Anilox Roller Ultrasonic Cleaning Machine Roller Rubber Roller Ink Cleaning Equipment

Due to prolonged printing time, the mesh of the anilox roller is easily blocked by dirt such as ink, paint, and adhesive. If not cleaned properly at this time, it will affect the quality of printing and the normal use of the anilox roller. The anilox roller ultrasonic cleaning machine utilizes the small water bubbles…

Anilox Roller Ultrasonic Cleaning Machine Roller Rubber Roller Ink Cleaning Equipment

Due to prolonged printing time, the mesh of the anilox roller is easily blocked by dirt such as ink, paint, and adhesive. If not cleaned properly at this time, it will affect the quality of printing and the normal use of the anilox roller. The anilox roller ultrasonic cleaning machine utilizes the small water bubbles generated by ultrasonic waves to directly enter the interior of the mesh and carry residual ink out of the mesh hole.

Cleaning method:

- First, evenly apply the concentrated cleaning solution of the anilox roller to the anilox roller. According to the degree of blockage of the anilox roller, leave it for several hours, then put it into an ultrasonic cleaning machine for cleaning, and then rinse it with clean water.

- Directly mix the water-soluble roller cleaning agent according to the ratio, and place the anilox roller in the cleaning tank for cleaning. Ultrasonic cleaning of the anilox roller provides fast cleaning speed, effective cleaning (as clean as new), and does not damage the anilox roller. The ultrasonic cleaning machine can be customized according to different specifications of the printing factory’s anilox rollers.

Main materials used:

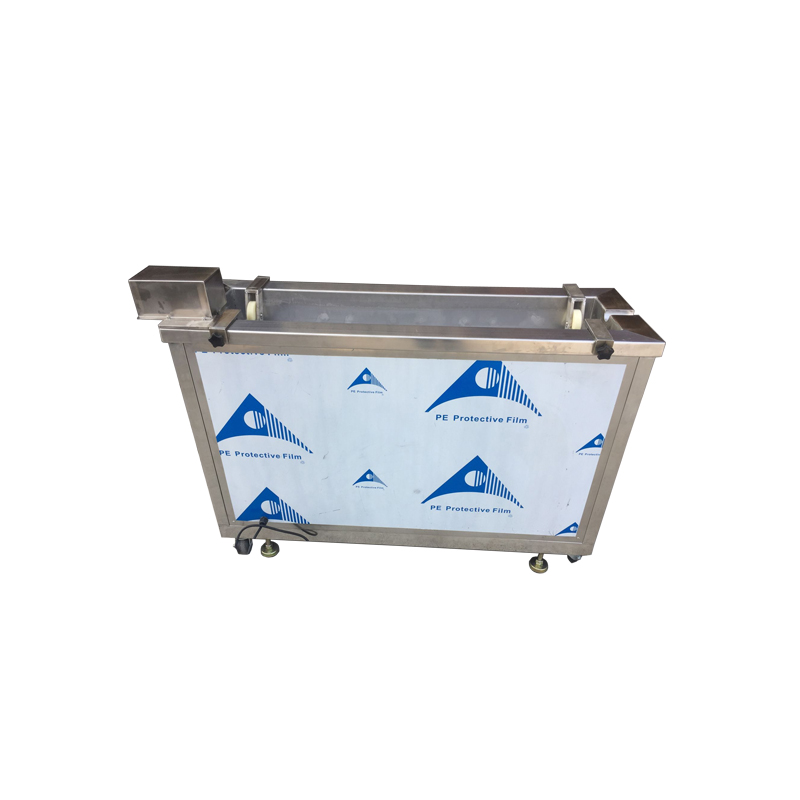

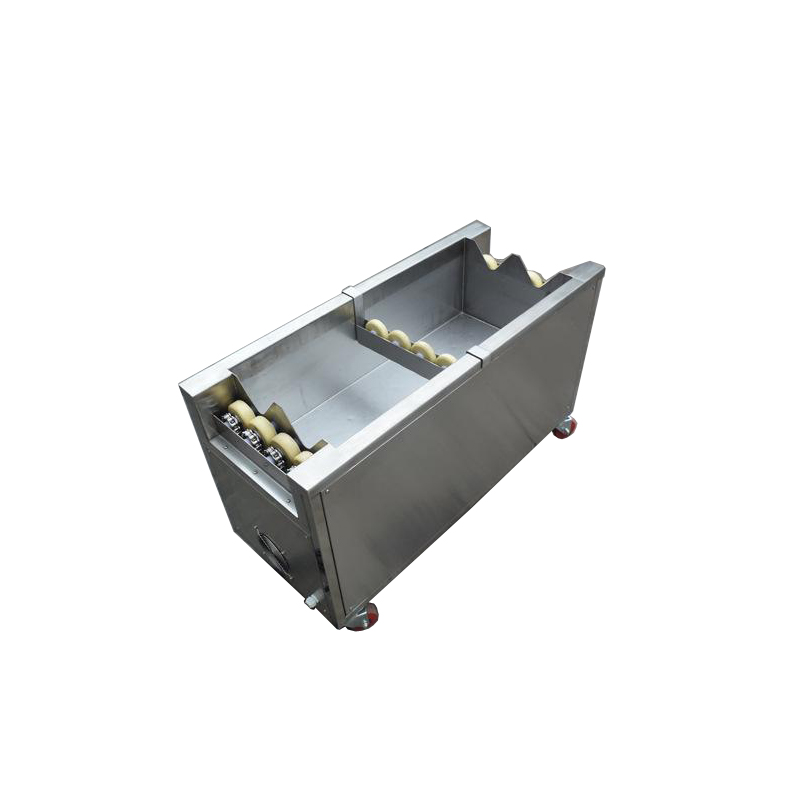

- The inner groove is made of SUS304 stainless steel plate with precision waterproof welding, with strong surface corrosion resistance and beautiful appearance.

- High Q-value PZT transducers are used to ensure uniform and stable ultrasound.

- Adopting Japanese bonding technology and Swiss imported bonding adhesive.

- The ultrasonic cleaning machine for the anilox roller adopts an IGBT high-frequency dual frequency sweep circuit, which automatically controls the rotation mechanism and adjusts the cleaning time of the anilox roller rotation and pause, thereby improving the cleaning efficiency and cleanliness of the anilox roller without damaging the anilox roller.

- Adopting a new type of thickened cast aluminum heating plate, it has high heating efficiency and an ultra long service life.

Anilox Roller Ultrasonic Cleaning Machine Roller Rubber Roller Ink Cleaning Equipment

标签:Anilox Roller Ultrasonic Cleaning Machine, Ultrasonic Cleaning Machine Roller Rubber Roller Ink

Send Inquiry

Printing Rollers And Anilox Ultrasonic Cleaning Nachine And Digital Ultrasonic Generator

Printing Rollers And Anilox Ultrasonic Cleaning Nachine And Digital Ultrasonic Generator Printing Ultrasonic Anilox Roller Cleaning Machine And Digital Ultrasonic Generator

Printing Ultrasonic Anilox Roller Cleaning Machine And Digital Ultrasonic Generator Customized Tank Built-in Motor Rotate Automatically Industrial Anilox Rolerl Ultrasonic Cleaning Machine

Customized Tank Built-in Motor Rotate Automatically Industrial Anilox Rolerl Ultrasonic Cleaning Machine Industrial Ceramic Anilox Roll Ultrasonic Cleaning Equipment And Ultrasonic Cleaning Drivers Generator

Industrial Ceramic Anilox Roll Ultrasonic Cleaning Equipment And Ultrasonic Cleaning Drivers Generator Automatic Anilox Roll Ultrasonic Cleaning Machine Customized Single Tank Industrial Ultrasonic Cleaner

Automatic Anilox Roll Ultrasonic Cleaning Machine Customized Single Tank Industrial Ultrasonic Cleaner Multi Four Roll Ultrasonic Cleaner Ceramic Anilox Roll Cleaning Systems With Ultrasonic Power Generator

Multi Four Roll Ultrasonic Cleaner Ceramic Anilox Roll Cleaning Systems With Ultrasonic Power Generator Anilox Ceramic Roller Ultrasonic Clean Machine Flexo Printing Anilox Cylinder Cleaning Cleaner Machine

Anilox Ceramic Roller Ultrasonic Clean Machine Flexo Printing Anilox Cylinder Cleaning Cleaner Machine 126 Liter SUS304 Anilox Rolls Ultrasonic Cleaner 400L For Screen Roll Cleaning Systems

126 Liter SUS304 Anilox Rolls Ultrasonic Cleaner 400L For Screen Roll Cleaning Systems 138L Industrial Ultrasonic Anilox Roller Cleaner Cleaning Machine to Clean Ink Glue Silicone Oil

138L Industrial Ultrasonic Anilox Roller Cleaner Cleaning Machine to Clean Ink Glue Silicone Oil Automatic Ultrasonic Printing Cylinder Cleaner Anilox Roll Ultrasonic Cleaning Machine For Dirty Anilox Cleaner

Automatic Ultrasonic Printing Cylinder Cleaner Anilox Roll Ultrasonic Cleaning Machine For Dirty Anilox Cleaner Ultrasonic Anilox Roller Cleaning Machine for Printing Industry With 40khz Frequency Ultrasonic Generator

Ultrasonic Anilox Roller Cleaning Machine for Printing Industry With 40khz Frequency Ultrasonic Generator Coating Anilox Roller Ultrasonic Cleaning Machine With Ultrasonic Cleaner Generator

Coating Anilox Roller Ultrasonic Cleaning Machine With Ultrasonic Cleaner Generator