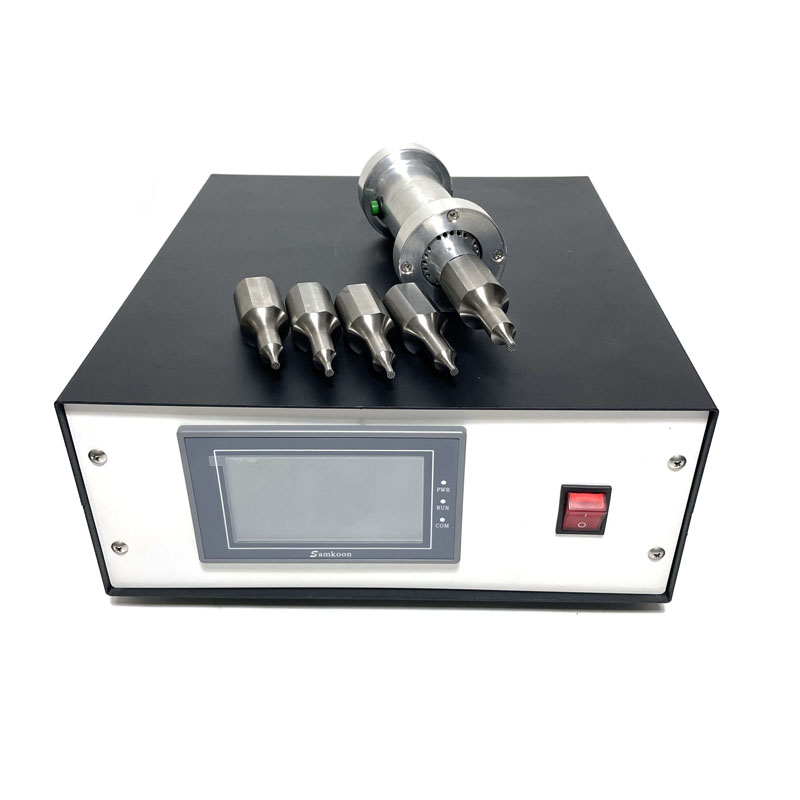

Handheld Plastic Welding Machine of Ultrasonic Spot Welding Machine and Ultrasonic Spot Welder

Ultrasonic plastic riveting technology is a simple, low-cost, efficient, and simple permanent fixed assembly technology that can rivet and assemble plastic parts with metal parts or other components of non weldable materials. The riveting surface is beautiful, has good smoothness, and is not prone to cracking and emb…

Handheld Plastic Welding Machine of Ultrasonic Spot Welding Machine and Ultrasonic Spot Welder

Ultrasonic plastic riveting technology is a simple, low-cost, efficient, and simple permanent fixed assembly technology that can rivet and assemble plastic parts with metal parts or other components of non weldable materials. The riveting surface is beautiful, has good smoothness, and is not prone to cracking and embrittlement. This technology has the advantages of advanced technology, reasonable structure, no vibration, no noise, no pollution, and high processing quality. It can be widely used in the production of aerospace and military industries, electronic appliances, instruments, automobiles, household appliances, hardware, and other industries, especially suitable for the processing of various automotive components. The automotive components processed using this technology have been used in BMW, VW, BENZ, FORD, ROVER, TOYOTA, etc NISSAN and other vehicle models have been applied.

The basic principle of the plastic joint technology reserved by hot riveting is to make the riveting columns, ribs, or vertical ribs on the molded parts pass through the prefabricated holes on the stamped metal plate, and use non-contact heating technology to heat the protruding parts of the riveting columns on the plastic parts that pass through the metal surface. When the protruding rivet column on the metal surface is softened by heat, it is then compressed with a specially designed metal forming rivet head, so that the plastic rivet column is reshaped in a locked state after being heated, and then riveted after cooling. By using a specific shape of rivet head, it is possible to achieve flush riveting, countersunk riveting (countersunk riveting), hemispherical riveting, arc flange riveting, vertical rib ribbed riveting, folded edge inlay and wrapping of plastic rivet columns, etc.

| Type | power (W) | Frequency | Welding time | Contains |

| PU-HH300W | 300W | 20khz,28khz,30khz,35khz,40khz | 0.1-3sec | generator , transducer ,horn,head |

| PU-HH500W | 500W | 20khz,28khz,30khz | 0.1-3sec | generator , transducer ,horn,head |

| PU-HH900W | 900W | 20khz,28khz,30khz | 0.1-3sec | generator , transducer ,horn,head |

| PU-HH1000W | 1000W | 20khz,28khz | 0.1-3sec | generator , transducer ,horn,head |

| PU-HH1200W | 1200W | 20khz,28khz | 0.1-3sec | generator , transducer ,horn,head |

Handheld Plastic Welding Machine of Ultrasonic Spot Welding Machine and Ultrasonic Spot Welder

标签:Handheld Plastic Welding Machine, Ultrasonic Spot Welding Machine and Ultrasonic Spot Welder

Send Inquiry

28kHz 900W Ultrasonic Spot Welding Machine Portable Hand-held Point Welding Machine And Multi-Function Generator

28kHz 900W Ultrasonic Spot Welding Machine Portable Hand-held Point Welding Machine And Multi-Function Generator 28khz 1200w Portable Ultrasonic Plastic Welder Spot Welding Machine For Strap Velcro

28khz 1200w Portable Ultrasonic Plastic Welder Spot Welding Machine For Strap Velcro 500W 35KHZ Single Head Earloop Ultrasonic Spot Welding Machine And Power Generator

500W 35KHZ Single Head Earloop Ultrasonic Spot Welding Machine And Power Generator Manual Ultrasonic Spot Welder Welding Hand Held Portable Ultrasonic Spot Welder With Wave Generator

Manual Ultrasonic Spot Welder Welding Hand Held Portable Ultrasonic Spot Welder With Wave Generator 28Khz 500W Ultrasonic Spot Welding Machine Ultrasonic Welder For Non-woven Fabric Welding Machine

28Khz 500W Ultrasonic Spot Welding Machine Ultrasonic Welder For Non-woven Fabric Welding Machine Portable Ultrasonic Welder Hand Gun Ultrasonic Spot Welder Gun Type Ultrasonic Spot Welder Machine For Automotive Parts

Portable Ultrasonic Welder Hand Gun Ultrasonic Spot Welder Gun Type Ultrasonic Spot Welder Machine For Automotive Parts 800w 28khz Mini Ultrasonic Mask Earloop Ear Wire Spot Welder Welding Machine

800w 28khz Mini Ultrasonic Mask Earloop Ear Wire Spot Welder Welding Machine Portable Customized HandHeld Ultrasonic Spot Welding Machine For Face Mask Clamp Ultrasonic Hand Welder

Portable Customized HandHeld Ultrasonic Spot Welding Machine For Face Mask Clamp Ultrasonic Hand Welder Handheld Spot Welder Hot Sale 28Khz Portable Ultrasonic Spot Welder Handheld Spot Welding Machine

Handheld Spot Welder Hot Sale 28Khz Portable Ultrasonic Spot Welder Handheld Spot Welding Machine Portable Hand Held Intelligent Ultrasonic Plastic Spot Welder 35kHz Portable Ultrasonic Plastic Welder

Portable Hand Held Intelligent Ultrasonic Plastic Spot Welder 35kHz Portable Ultrasonic Plastic Welder Handheld Ultrasonic Welder 30khz Machine Machinery Ultrasonic Spot Welding Machine Gun Portable Ultrasonic Hand Welder

Handheld Ultrasonic Welder 30khz Machine Machinery Ultrasonic Spot Welding Machine Gun Portable Ultrasonic Hand Welder Ultrasonic Handheld Welder Ultrasonic Spot Welding Machine Portable Spot Ultrasonic Welder Bonding Machine Plastic Welding

Ultrasonic Handheld Welder Ultrasonic Spot Welding Machine Portable Spot Ultrasonic Welder Bonding Machine Plastic Welding