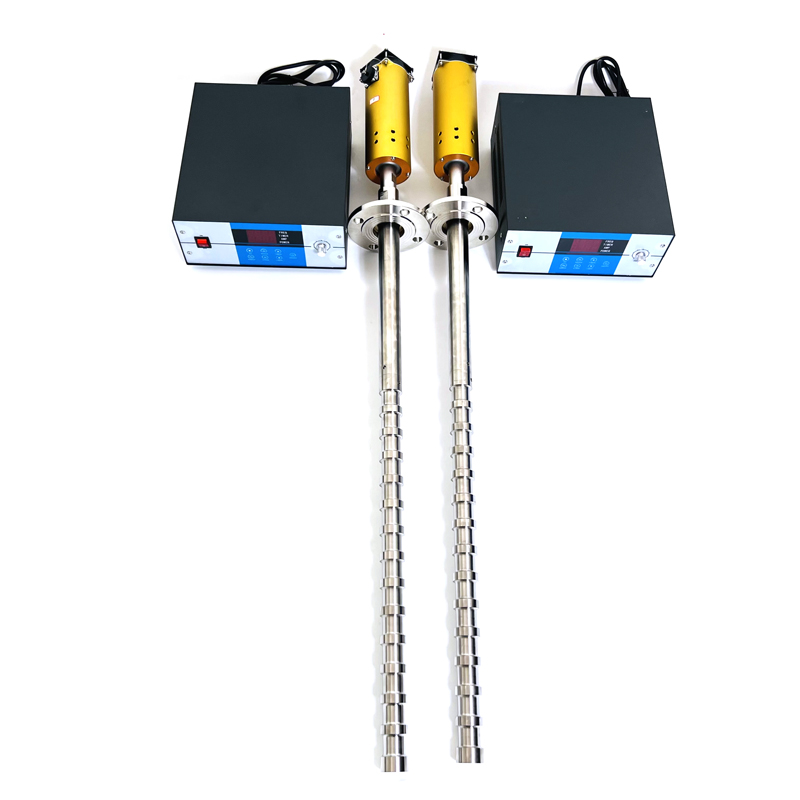

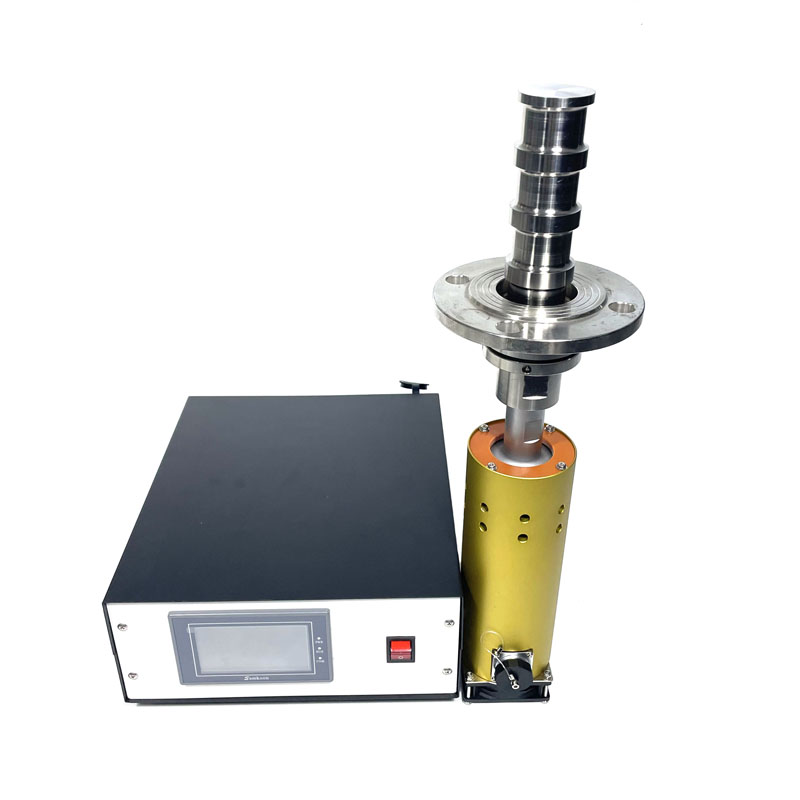

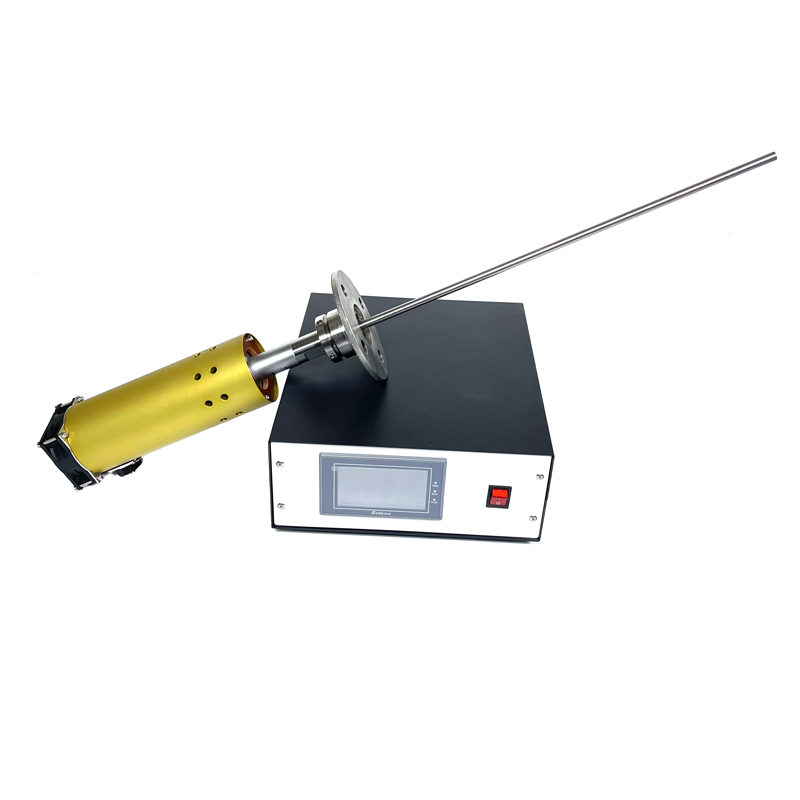

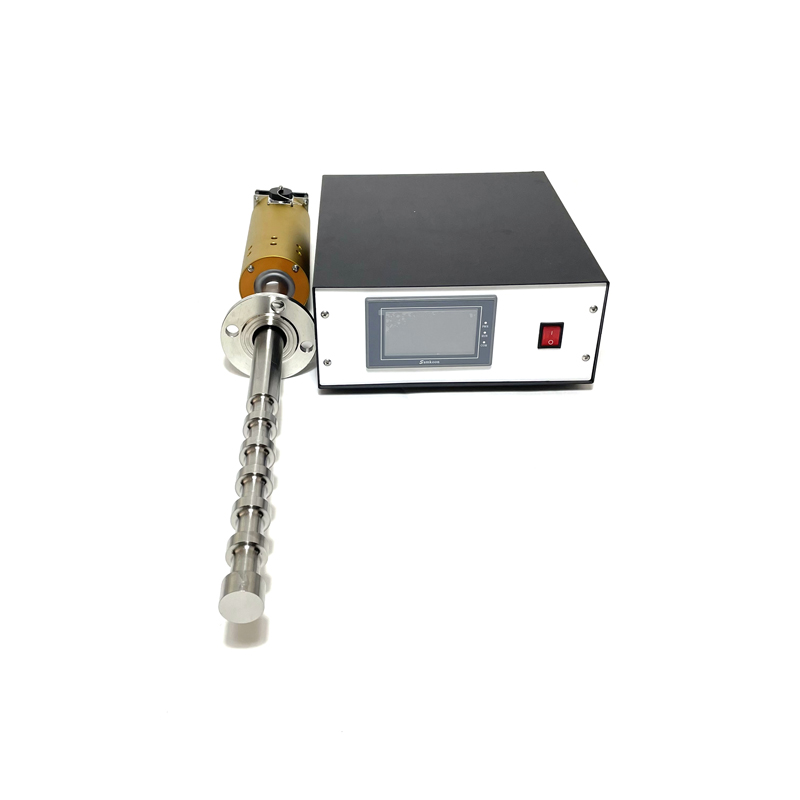

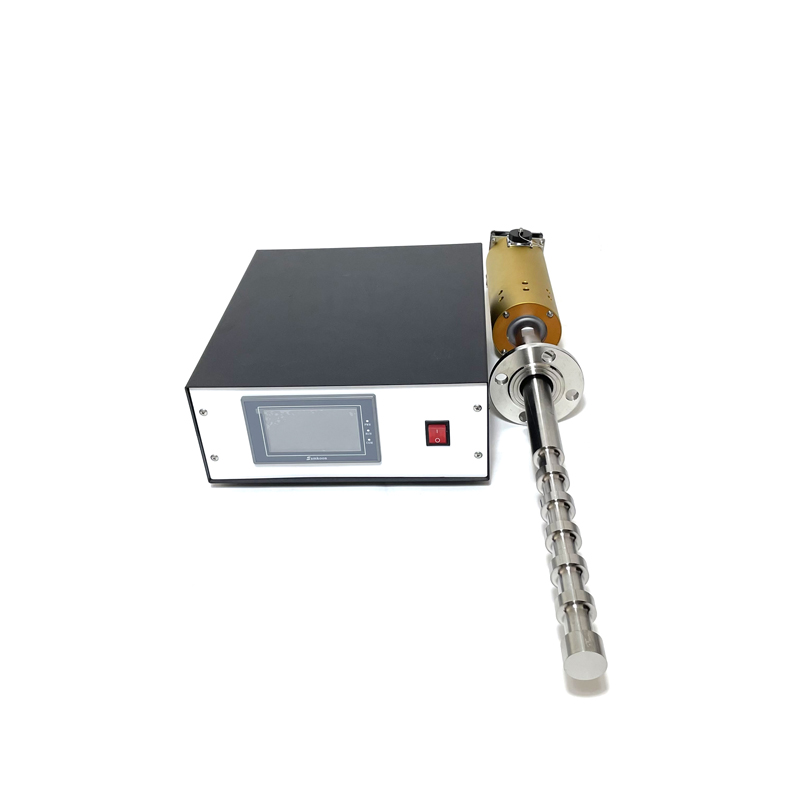

Industrial Ultrasonic Nano Dispersing Machine Ultrasonic Homogenize Emulsify System With Signal Generator

Due to the wide range of applications of ultrasonic vibration rods, generally speaking, ultrasonic vibration rods are also known as ultrasonic vibration rods. Compared to traditional ultrasonic vibration plates, they have the characteristics of wider application range and longer service life. In terms of industrial a…

Due to the wide range of applications of ultrasonic vibration rods, generally speaking, ultrasonic vibration rods are also known as ultrasonic vibration rods. Compared to traditional ultrasonic vibration plates, they have the characteristics of wider application range and longer service life. In terms of industrial applications, the use of ultrasonic vibration rods for cleaning, extraction, chemical reactions, scale prevention, water treatment, etc. is a very mature and widely used technology. Ultrasonic vibration rod is a device that utilizes the alternating period of positive and negative pressure during the transmission process of ultrasonic waves. During the positive phase, it compresses the medium molecules, increasing the original density of the medium; When the phase is negative, the molecules in the medium are sparse and discrete, resulting in a decrease in the density of the medium. The use of ultrasound in the processing of biomass resources has been a hot topic of research and development in recent years, among which * * representative works are the enhanced extraction of plant active ingredients using ultrasound and the preparation of biodiesel using ultrasound. The cavitation effect of performance indicators is generated around the vibrating rod, and the ultrasonic energy is evenly distributed around the tank or cylinder, thereby achieving * * * excellent cleaning effect. The power output of the ultrasonic vibration rod is not affected by load changes such as liquid level, tank capacity, and temperature difference, and the power output is stable and uniform. Ultrasonic vibration rods have a service life of more than 1.5 times that of traditional ultrasonic vibration plates. The circular tube design allows the vibrating rod to be easily installed in any position within the groove. Ensure complete sealing and waterproofing. Scope of application Ultrasonic vibrator is applicable to the cleaning of workpieces in various industries, such as the cleaning of precision electronic parts, clock parts, optical glass parts, hardware and machinery parts, jewelry, semiconductor silicon chips, polyester filter elements/spinneret, medical devices, and the cleaning of parts before and after electroplating. Ultrasonic vibrating rod is suitable for Chinese medicine extraction, cleaning the inner wall of thick wall metal pipes, online ultrasonic anti scaling of boilers, ultrasonic cleaning in vacuum/pressure situations, various pipeline type ultrasonic treatment and pipeline type sonochemistry treatment.

| Tubular EquipmentType | Tubular TransducerType | Frequency(KHz) | UltrasoundOutput(W) | Total Length(mm) | Diameter(mm) | Static Capacity(pF±10%) |

| PU-UE1 | US-61 | 15-28 | 1000 | 500 | Φ50-55 | 68000 |

| PU-UE5 | US-25 | 15-28 | 1500 | 850 | Φ50-55 | 68000 |

| PU-UE6 | US-16 | 15-28 | 2000 | 1100 | Φ50-55 | 132000 |

标签:Industrial Ultrasonic Nano Dispersing Machine, Ultrasonic Homogenize Emulsify System, Ultrasonic Homogenize Emulsify System With Signal Generator, ultrasonic vibration rods

Send Inquiry

20khz 1000W Ultrasonic Rod Transducer Biodiesel Reactors Ultrasonic Emulsification Reactor

20khz 1000W Ultrasonic Rod Transducer Biodiesel Reactors Ultrasonic Emulsification Reactor 1000W 20KHZ Ultrasonic Cavitation Reactor Biodiesel Production And Power Supply Generator

1000W 20KHZ Ultrasonic Cavitation Reactor Biodiesel Production And Power Supply Generator Ultrasonic Oil Extractor Ultrasonic Sonochemistry Reactor Disperser Emulsifying Homogenizer Liquid Processor

Ultrasonic Oil Extractor Ultrasonic Sonochemistry Reactor Disperser Emulsifying Homogenizer Liquid Processor 20kHz Ultrasonic Sonochemistry Tube Flow-Through Reactor Ultrasonic Reactor Suppliers

20kHz Ultrasonic Sonochemistry Tube Flow-Through Reactor Ultrasonic Reactor Suppliers Ultrasonic Emulsifying Dispersion 300W Ultrasonic Liquid Reactor Homogenizer With Generator

Ultrasonic Emulsifying Dispersion 300W Ultrasonic Liquid Reactor Homogenizer With Generator 20Khz 2600W Industrial Ultrasonic Assisted Herb Extraction Dispersing Emulsification Homogenizer

20Khz 2600W Industrial Ultrasonic Assisted Herb Extraction Dispersing Emulsification Homogenizer 3000W 20KHZ Ultrasonic Material Dispenser Industrial Ultrasonic Reactor

3000W 20KHZ Ultrasonic Material Dispenser Industrial Ultrasonic Reactor Ultrasonic Equipment For Extraction Ultrasonic Cavitation Reactor Ultrasonic Sonochemistry Biodiesel Extraction

Ultrasonic Equipment For Extraction Ultrasonic Cavitation Reactor Ultrasonic Sonochemistry Biodiesel Extraction Sonochemistry Processor Ultrasonic Biodiesel Reactor Industrial Ultrasonic Emulsifier Biodiesel

Sonochemistry Processor Ultrasonic Biodiesel Reactor Industrial Ultrasonic Emulsifier Biodiesel 2000W 20KHZ Ultrasonic Processor Sonochemistry Biodiesel Reactor Laboratory Ultrasonic Sonochemistry Biodiesel Reactor

2000W 20KHZ Ultrasonic Processor Sonochemistry Biodiesel Reactor Laboratory Ultrasonic Sonochemistry Biodiesel Reactor Laboratory Ultrasonic Liquid Processor Homogenizer Ultrasonic Homogenizer Machine Emulsifier

Laboratory Ultrasonic Liquid Processor Homogenizer Ultrasonic Homogenizer Machine Emulsifier Industrial Extractor Extraction Equipment Laboratory Ultrasonic Liquid Sonochemistry Processor Reactor

Industrial Extractor Extraction Equipment Laboratory Ultrasonic Liquid Sonochemistry Processor Reactor