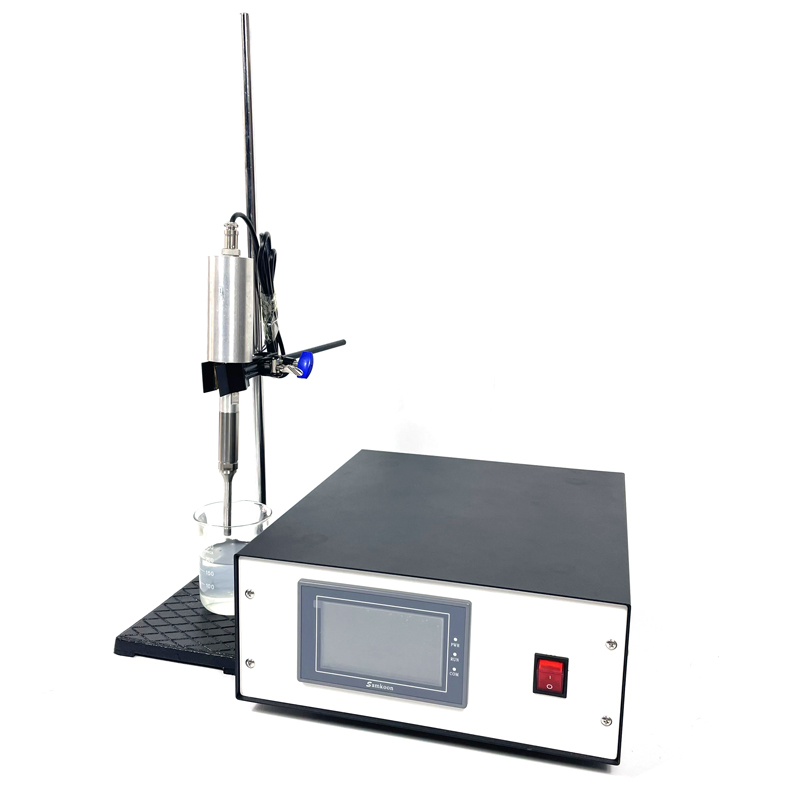

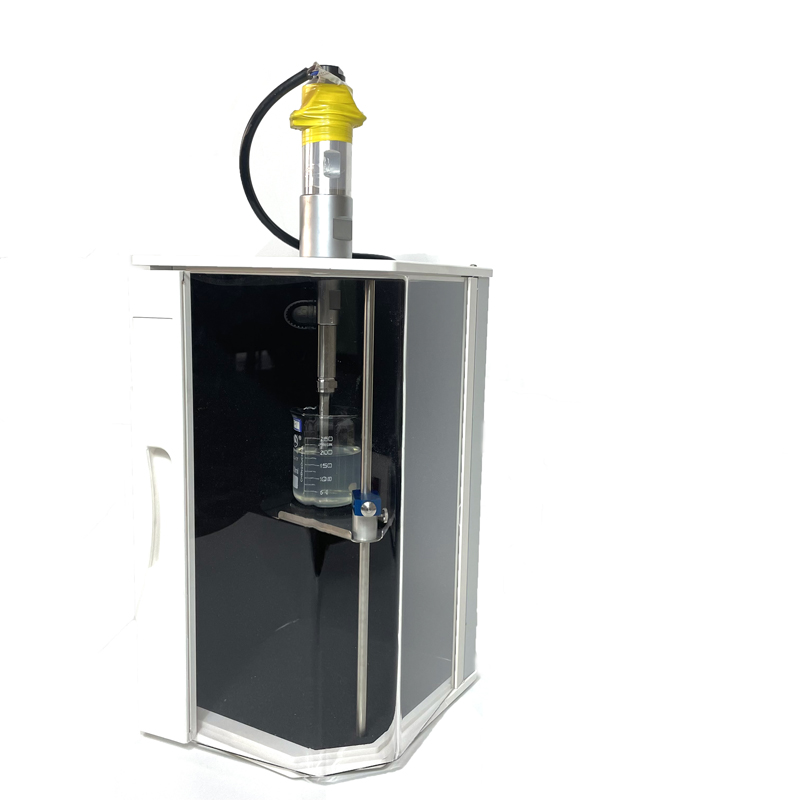

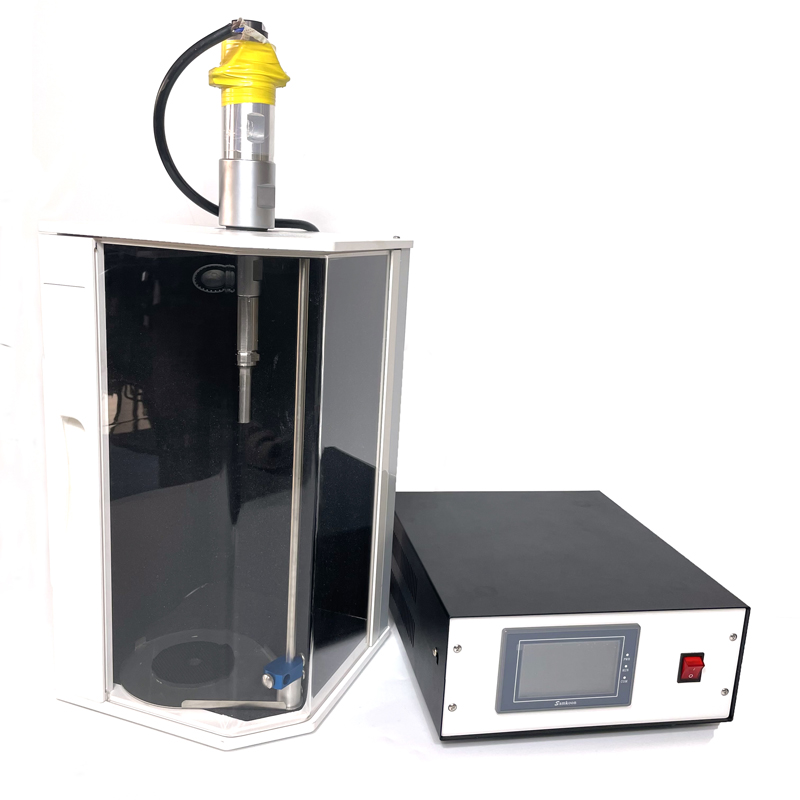

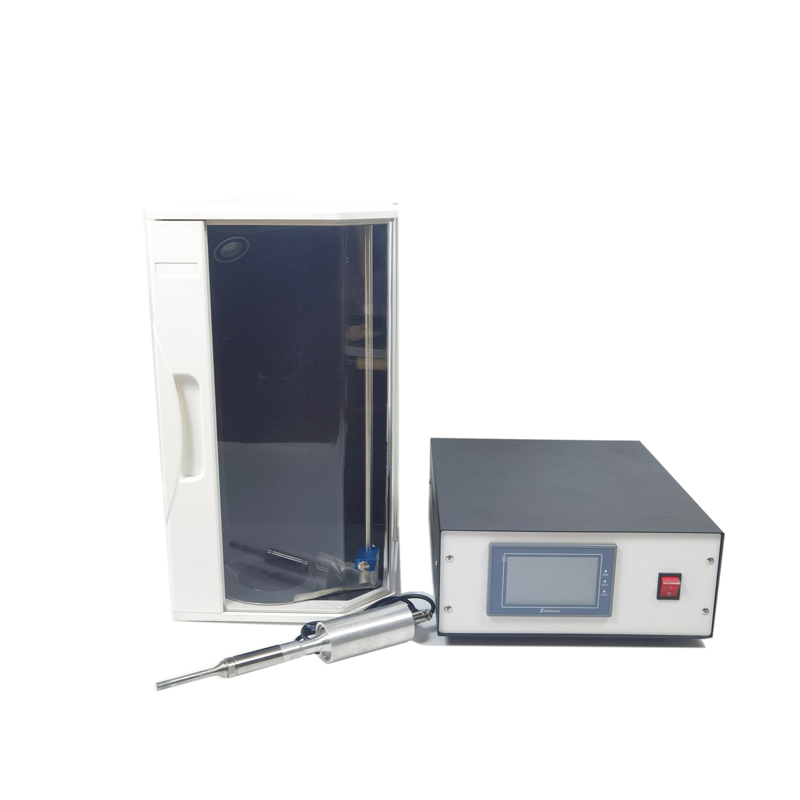

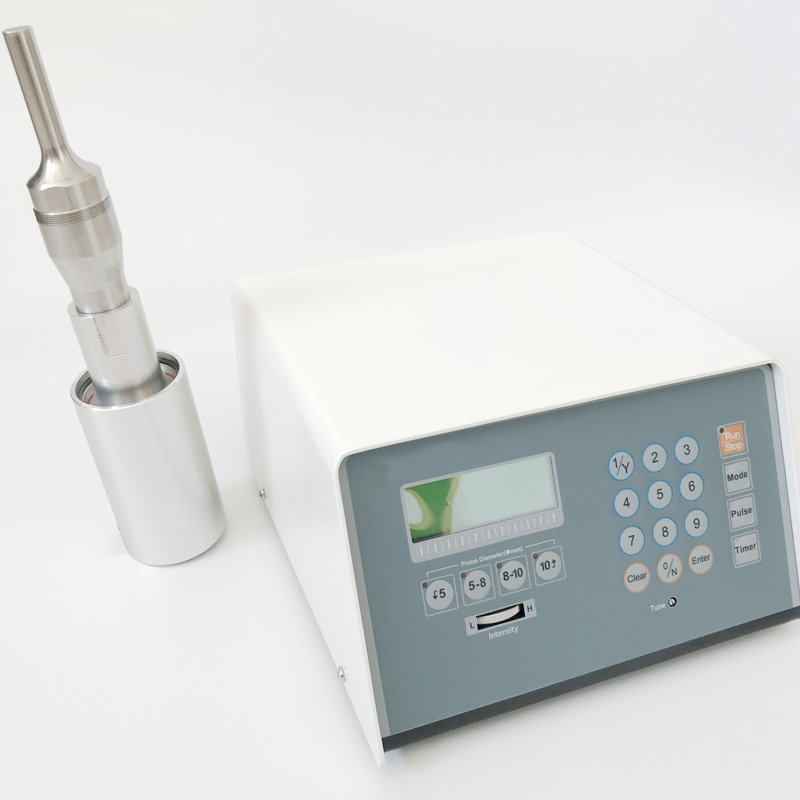

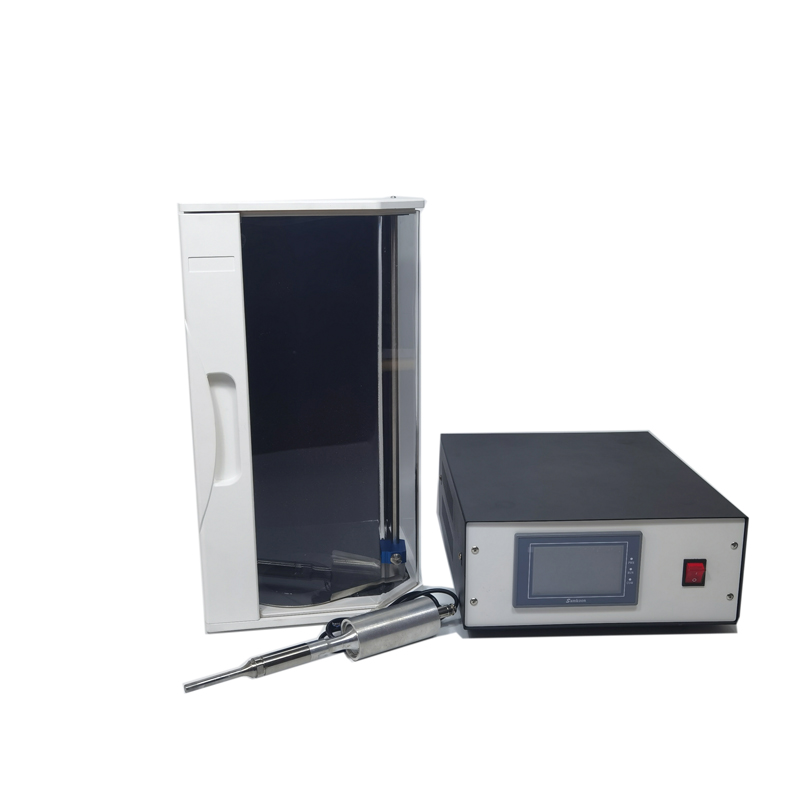

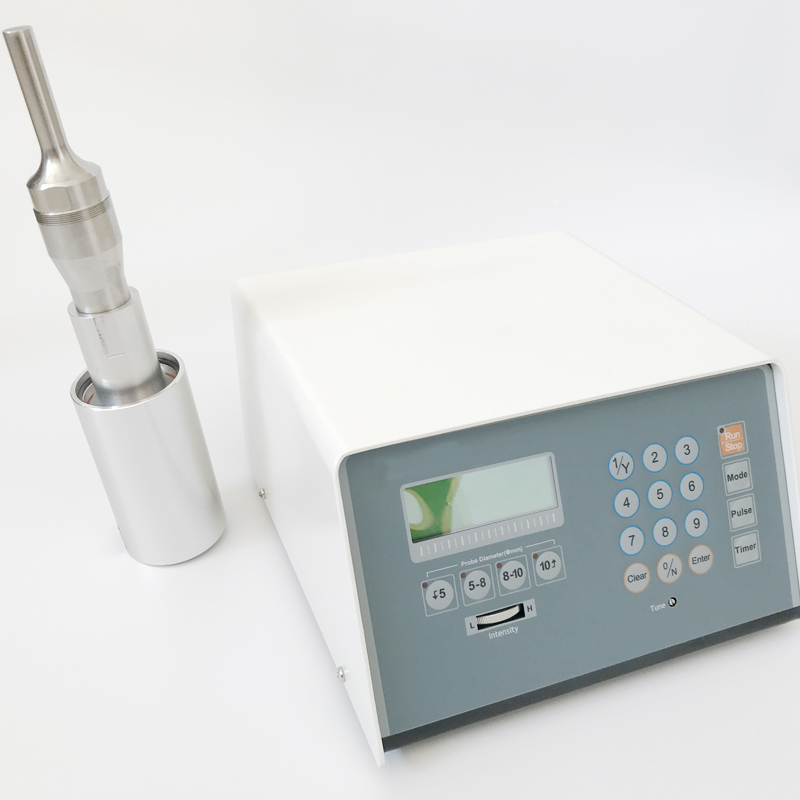

Lab Ultrasonic Chemical Homogenizer Ultrasonic Processor Biodiesel Processor Ultrasonic Homogenizer

With the continuous progress of technology, ultrasonic technology has been widely applied in various fields. Among them, ultrasonic liquid processors, as an efficient and environmentally friendly liquid processing method, are gradually receiving attention from the industry. Ultrasonic liquid processors utilize the ca…

Lab Ultrasonic Chemical Homogenizer Ultrasonic Processor Biodiesel Processor Ultrasonic Homogenizer

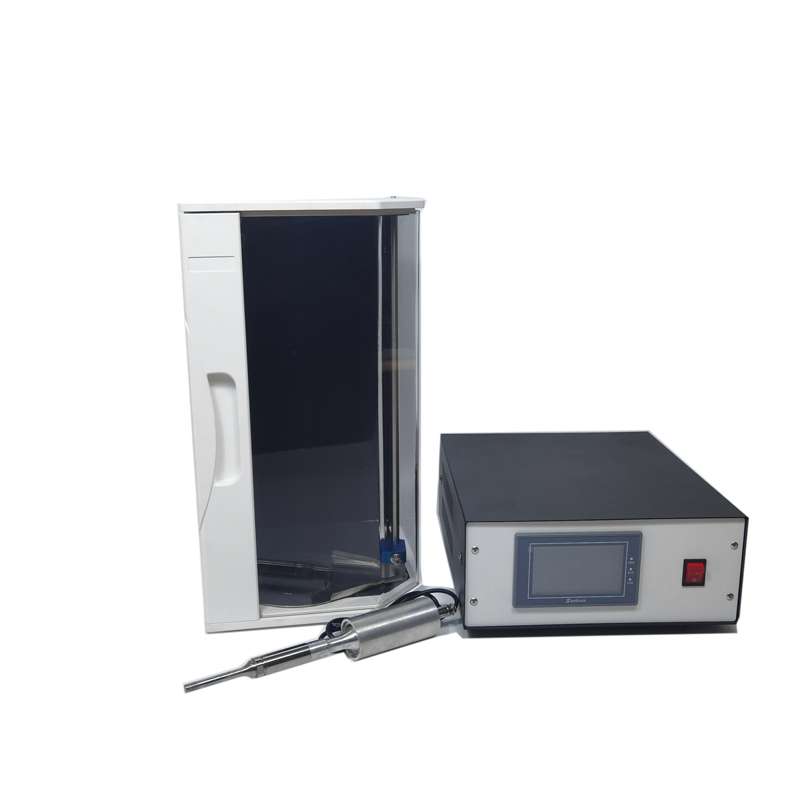

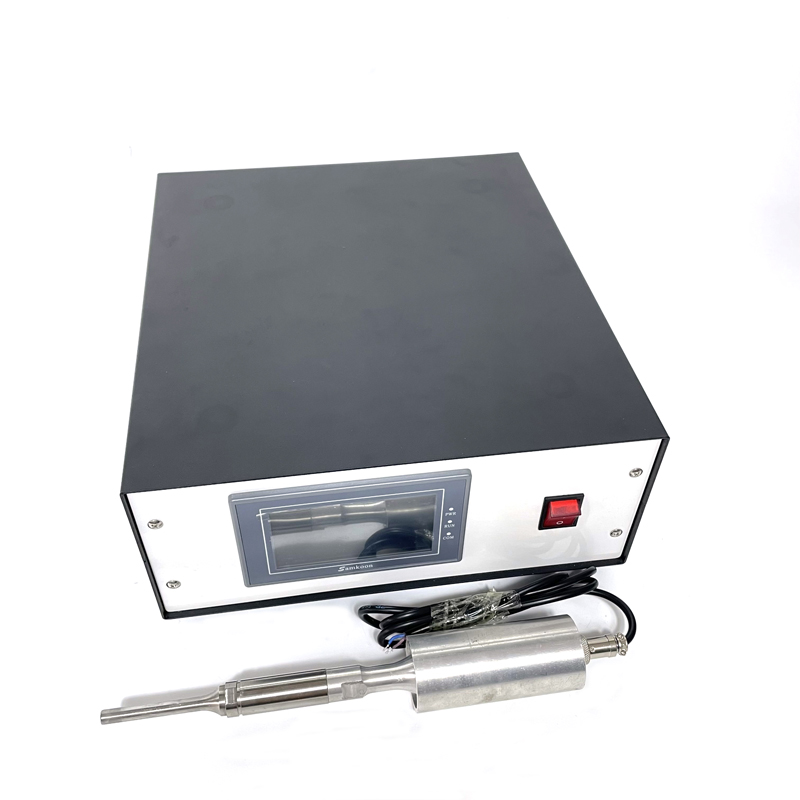

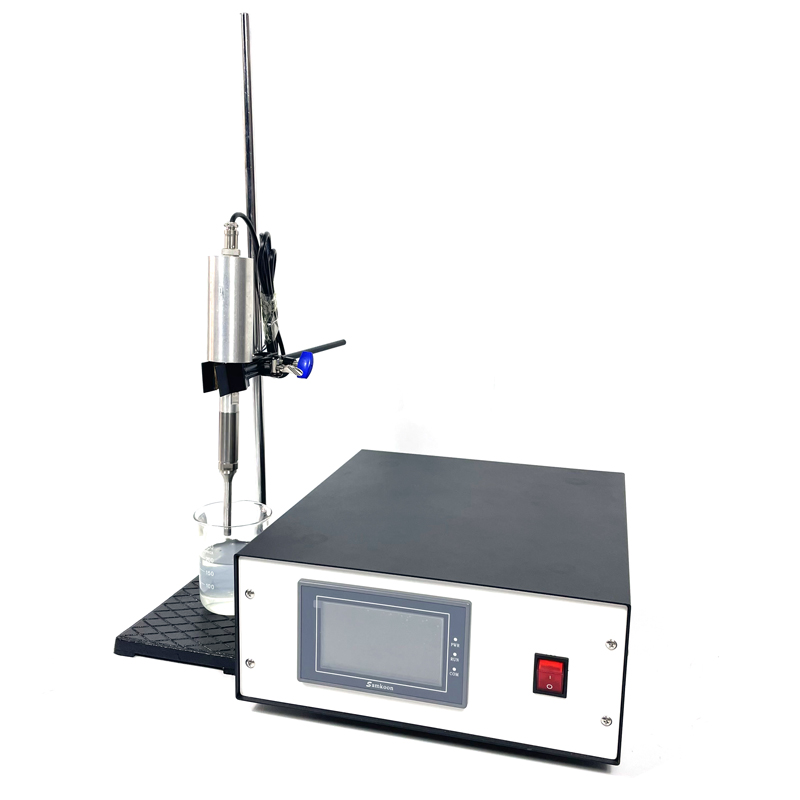

With the continuous progress of technology, ultrasonic technology has been widely applied in various fields. Among them, ultrasonic liquid processors, as an efficient and environmentally friendly liquid processing method, are gradually receiving attention from the industry. Ultrasonic liquid processors utilize the cavitation, vibration, and microfluidic effects of ultrasound to achieve efficient separation and conversion of various pollutants in liquids. The core lies in the fact that the vibration energy of sound waves can promote the generation of a large number of tiny bubbles in the liquid. These bubbles rapidly expand under the negative pressure phase of sound waves and collapse rapidly during the positive pressure phase, creating a local high-temperature and high-pressure environment. The chemical reactions and physical effects under extreme conditions can effectively decompose organic matter, inactivate microorganisms, and mineralize harmful substances.

With the increasing awareness of environmental protection and the continuous progress of technology, the application prospects of ultrasonic liquid processors in the future are very broad. Firstly, with breakthroughs in materials science, new and efficient energy exchange materials will further optimize the performance of ultrasonic fluid processors. Secondly, an intelligent control system will help achieve automatic and remote control of equipment, improving processing efficiency. Finally, with the development of Internet of Things technology, ultrasonic liquid processors are expected to be integrated with systems such as smart cities and smart agriculture, providing strong support for building a sustainable future society.

Ultrasonic liquid processor, as an efficient and environmentally friendly liquid treatment technology, has broad application prospects and huge development potential. With the advancement of technology and the deepening of research, ultrasonic liquid treatment technology will continue to improve, providing more possibilities for solving the environmental and resource problems facing the world. Let’s look forward to greater breakthroughs and progress in this field in the future.

| Type | Power (w) | Output Amplitude | Available Converter |

| PU-100UP | 100 | 1/8″3/16″1/4″ | 100ul~80ml 1%~99% |

| PU-150UP | 150 | 1/8″3/16″1/4″ | 100ul~100ml 1%~99% |

| PU-250UP | 250 | 1/8″3/16″1/4″ | 100ul~200ml 1%~99% |

| PU-500UP | 500 | 1/8″3/16″1/4″1/2″ | 250ul~500ml 1%~99% |

| PU-800UP | 800 | 1/8″3/16″1/4″1/2″3/4″ | 250ul~800ml 1%~99% |

Lab Ultrasonic Chemical Homogenizer Ultrasonic Processor Biodiesel Processor Ultrasonic Homogenizer

Send Inquiry

Sonicator 20K 2000W Laboratory Ultrasonic Cell Disruptor Homogenizer Rod Vibrator Medical Bioactive Compounds cell Disruption

Sonicator 20K 2000W Laboratory Ultrasonic Cell Disruptor Homogenizer Rod Vibrator Medical Bioactive Compounds cell Disruption 1500W Ultrasonic Sonicator Homogenizer Oli Emulsification Biological Sample Testing Herbs Extraction

1500W Ultrasonic Sonicator Homogenizer Oli Emulsification Biological Sample Testing Herbs Extraction 300W 20KHZ Lab Probe Ultrasonic Homogenizer Sonicator Cell Disruptor Mixer

300W 20KHZ Lab Probe Ultrasonic Homogenizer Sonicator Cell Disruptor Mixer Ultrasonic Homogenizer Sonicator Processor Cell Epoxy Resin Mixer Emulsifying Ultrasonic Probe

Ultrasonic Homogenizer Sonicator Processor Cell Epoxy Resin Mixer Emulsifying Ultrasonic Probe 1000W 20khz LCD Display Portable Medical Science Ultrasonic Cell Disruptor For Industrial

1000W 20khz LCD Display Portable Medical Science Ultrasonic Cell Disruptor For Industrial Lab/ Industrial Cell Disruptor Mixer Sonicator Processor Probe Ultrasonic Homogenizer

Lab/ Industrial Cell Disruptor Mixer Sonicator Processor Probe Ultrasonic Homogenizer Sonicator Ultrasonic Homogenizers Emulsifiers Ultrasonic Sonicator Processor Homogenizer

Sonicator Ultrasonic Homogenizers Emulsifiers Ultrasonic Sonicator Processor Homogenizer 1000W 20KHZ Laboratory Portable Ultrasonic Cell Disruptor for Ultrasound Homogenizer Sonicator

1000W 20KHZ Laboratory Portable Ultrasonic Cell Disruptor for Ultrasound Homogenizer Sonicator Ultrasonic Homogenizer Sonicator Cell Disruptor Mixer Ultrasonic Homogenizer Processor Manufacturer Lab Cell Crusher

Ultrasonic Homogenizer Sonicator Cell Disruptor Mixer Ultrasonic Homogenizer Processor Manufacturer Lab Cell Crusher Ultrasonic Cell Disruptor High Accurate Temperature Portable Ultrasonic Cell Disruptor

Ultrasonic Cell Disruptor High Accurate Temperature Portable Ultrasonic Cell Disruptor Lab Ultrasonic Cell Homogenizer Disruptor Crusher Lab Bench Top Ultrasonic Material Mixer Machine Cell Crusher

Lab Ultrasonic Cell Homogenizer Disruptor Crusher Lab Bench Top Ultrasonic Material Mixer Machine Cell Crusher 20khz Laboratory Cell Disruptor 1800W Ultrasonic Sonicator Homogenaizer Liquid Processor

20khz Laboratory Cell Disruptor 1800W Ultrasonic Sonicator Homogenaizer Liquid Processor