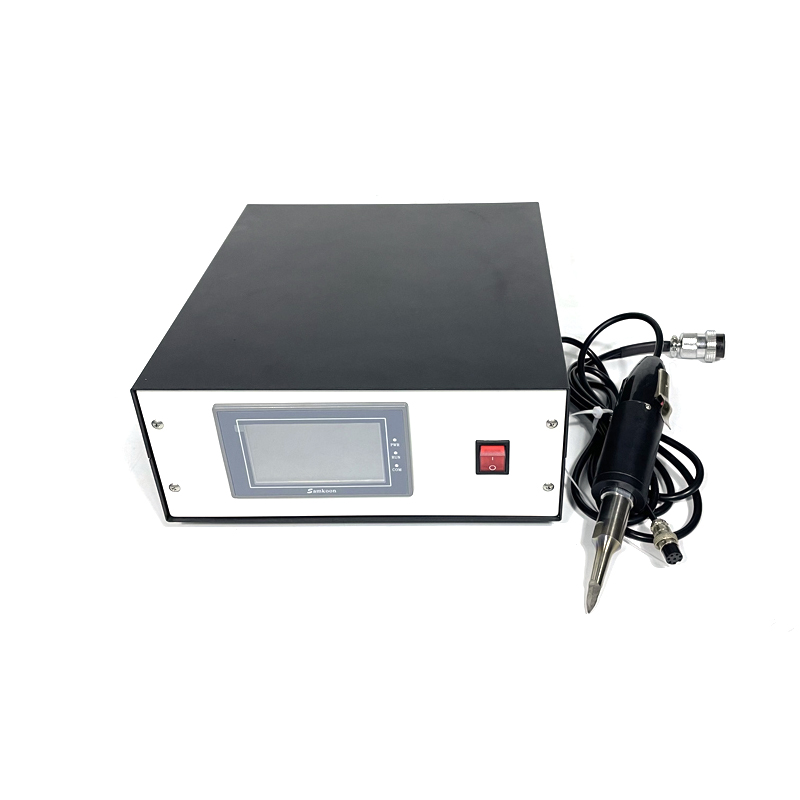

Ultrasonic Fabric Cutting Ultrasonic Cutting Blade Ultrasonic Fabric Cutting Systems Of Industrial Fabrics And Textiles

Advantages of handheld ultrasonic fabric cutting machine: Efficient and Accurate: The handheld ultrasonic fabric cutting machine uses ultrasonic technology for cutting, with extremely high cutting accuracy and speed, which can greatly improve production efficiency and reduce production costs.No vibration: Due to t…

Advantages of handheld ultrasonic fabric cutting machine:

- Efficient and Accurate: The handheld ultrasonic fabric cutting machine uses ultrasonic technology for cutting, with extremely high cutting accuracy and speed, which can greatly improve production efficiency and reduce production costs.

- No vibration: Due to the vibration energy of ultrasound acting on the cutting tool rather than directly on the fabric, it can avoid problems such as fabric deformation caused by tool vibration in traditional cutting methods.

- No burrs: Ultrasonic cutting technology can control the burrs on the cutting edge to a minimum range, making the product quality even better.

- Easy to operate: The handheld ultrasonic fabric cutting machine has a simple structure, convenient operation, and is easy to master.

With the continuous development of technology, handheld ultrasonic fabric cutting machines will be more widely used and promoted. In the future, handheld ultrasonic fabric cutting machines will become more intelligent and automated, further improving production efficiency and product quality. Meanwhile, with the continuous improvement of environmental awareness, handheld ultrasonic fabric cutting machines will pay more attention to environmental protection and energy-saving design, reducing negative impacts on the environment.

The handheld ultrasonic fabric cutting machine, as an advanced technological tool, has important application value and development prospects in the textile industry. With the continuous progress of technology and the expansion of application fields, it is believed that it will bring broader prospects and opportunities for the development of the textile industry.

| Type | power (W) | Frequency | Welding time | Contains |

| PU-QG100W | 100W | 30khz,35khz,40khz | 0.1-3sec | generator , transducer ,horn,head |

| PU-QG300W | 300W | 30khz,35khz,40khz | 0.1-3sec | generator , transducer ,horn,head |

| PU-QG500W | 500W | 30khz,35khz,40khz | 0.1-3sec | generator , transducer ,horn,head |

Send Inquiry

Ultrasonic Textile Cutter Cutting Machine Ultrasonic Cutter Knife Ultrasonic Multifunctional Hand-held Cutter

Ultrasonic Textile Cutter Cutting Machine Ultrasonic Cutter Knife Ultrasonic Multifunctional Hand-held Cutter 35KHZ 200W Ultrasonic Fabric Cutting Machine With High Power Ultrasonic Generator

35KHZ 200W Ultrasonic Fabric Cutting Machine With High Power Ultrasonic Generator 28KHZ or 35KHZ or 40KHZ Handheld Ultrasonic Cutting Knife / Cutting Machine For Cutting Rubber

28KHZ or 35KHZ or 40KHZ Handheld Ultrasonic Cutting Knife / Cutting Machine For Cutting Rubber Digital Manual Ultrasonic Plastic Cutting Knife Machine For Sonotrodo Wiper Seamless Textil System

Digital Manual Ultrasonic Plastic Cutting Knife Machine For Sonotrodo Wiper Seamless Textil System Straight Ultrasonic Knife Cloth Cutting Machine Manual Cutter Fabric Circle For Clothing Fabric Cutting

Straight Ultrasonic Knife Cloth Cutting Machine Manual Cutter Fabric Circle For Clothing Fabric Cutting Portable Ultrasonic Cutter Knife 35khz Handheld Plastic Fabric Cutter Knife Hand Held For Nonwoven With Glass Fibre

Portable Ultrasonic Cutter Knife 35khz Handheld Plastic Fabric Cutter Knife Hand Held For Nonwoven With Glass Fibre 35KHZ Handheld Ultrasonic Cutting Knife Raw Rubber Hand-Held Cutting Knife Ultrasonic Cutter Hand held

35KHZ Handheld Ultrasonic Cutting Knife Raw Rubber Hand-Held Cutting Knife Ultrasonic Cutter Hand held Cutter Knife Hand Held For Nonwoven With Glass Fibre Portable Sealing Ultrasonic Label Cutting Machine

Cutter Knife Hand Held For Nonwoven With Glass Fibre Portable Sealing Ultrasonic Label Cutting Machine Ultrasound Knife 30kHz Ultrasonic Cutter Machine For Cutting Rubber And Sound Generator

Ultrasound Knife 30kHz Ultrasonic Cutter Machine For Cutting Rubber And Sound Generator 35KHZ 600W Ultrasonic Fabric Hand Cutting Machine Cutter Knife And Multi-Function Generator

35KHZ 600W Ultrasonic Fabric Hand Cutting Machine Cutter Knife And Multi-Function Generator Ultrasonic Cutting Generator Knife For Plastic And Rubber Handheld Portable Ultrasonic Knife Cutter

Ultrasonic Cutting Generator Knife For Plastic And Rubber Handheld Portable Ultrasonic Knife Cutter Ultrasonic Hand-Held Cutting Knife Multi Function Hand Held Ultrasonic Cutter Knife For ABS / PP / PE

Ultrasonic Hand-Held Cutting Knife Multi Function Hand Held Ultrasonic Cutter Knife For ABS / PP / PE