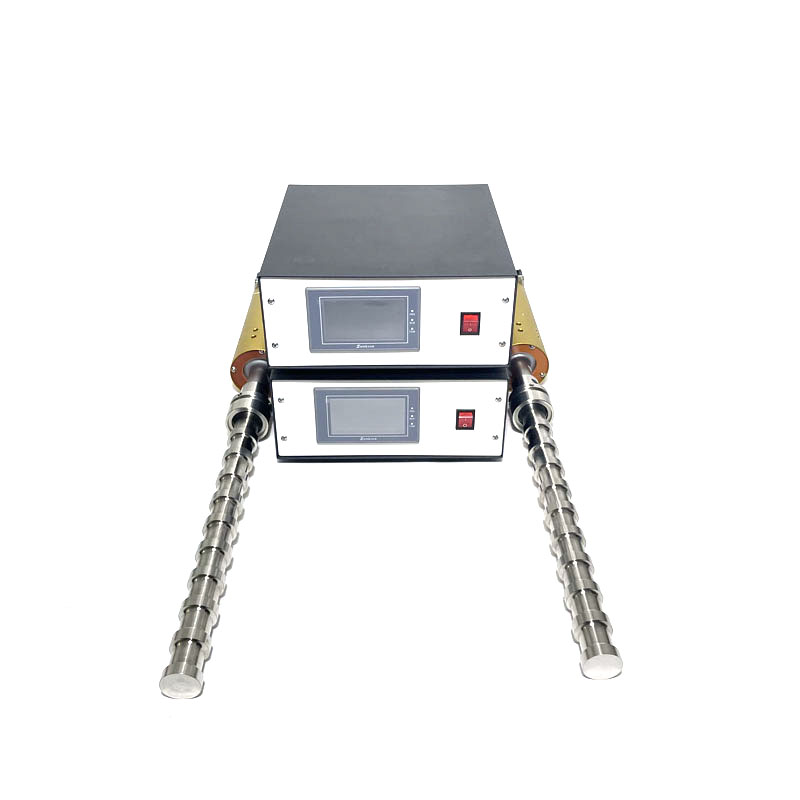

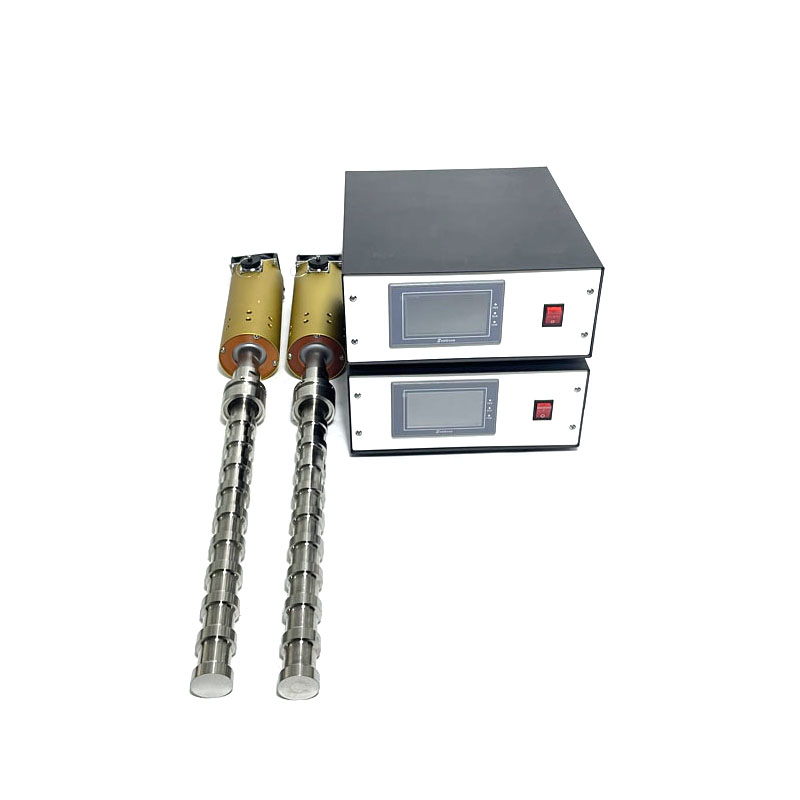

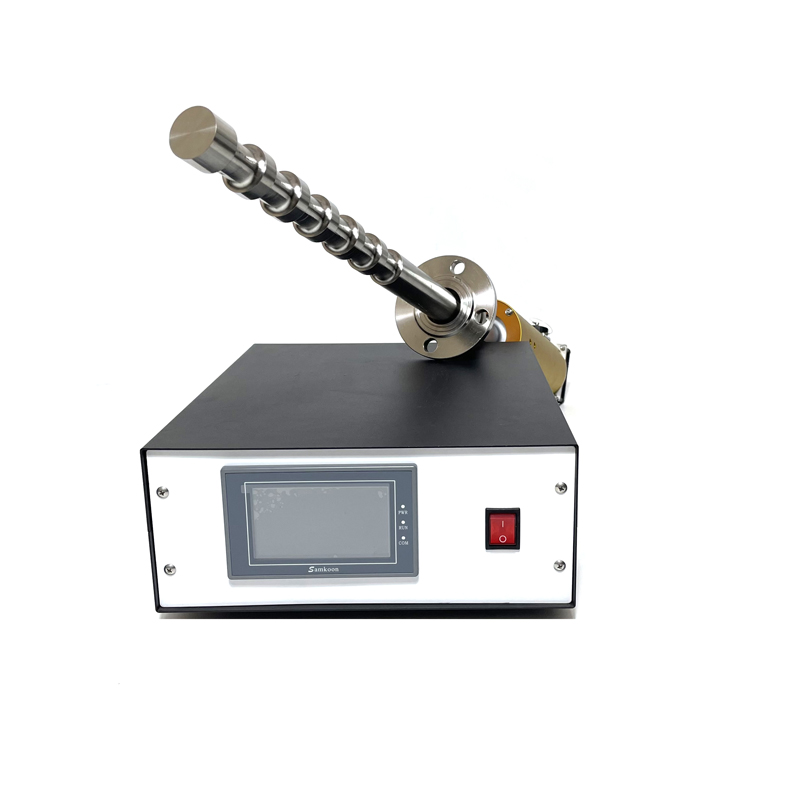

Waste Oil Animal Fat Food Mixers Ultrasonic Mixing Equipment For Biodiesel Nanoemulsion

Phenolic wastewater mainly comes from coking, coal gas, oil refining, chemical and pharmaceutical production processes using phenol or phenolic aldehyde as raw materials. It has a wide range of sources, a large quantity, high toxicity, and potential toxicity of carcinogenicity, teratogenicity, and mutagenicity. It is…

Waste Oil Animal Fat Food Mixers Ultrasonic Mixing Equipment For Biodiesel Nanoemulsion

Phenolic wastewater mainly comes from coking, coal gas, oil refining, chemical and pharmaceutical production processes using phenol or phenolic aldehyde as raw materials. It has a wide range of sources, a large quantity, high toxicity, and potential toxicity of carcinogenicity, teratogenicity, and mutagenicity. It is listed as a toxic and harmful wastewater that needs to be addressed in various countries. Conventional physical, chemical, and biological methods are difficult to meet the technical and economic requirements for purifying and treating such organic pollutants.

Phenol containing wastewater treatment poses a serious threat to human health. In order to further improve the treatment efficiency of phenol containing wastewater, domestic and foreign scholars have conducted extensive research on the treatment of phenol containing wastewater and developed various treatment methods. Phenol and its derivatives are common difficult to degrade and highly toxic organic compounds in wastewater. How to effectively degrade phenolic wastewater is one of the problems that must be solved in the field of environmental pollution control.

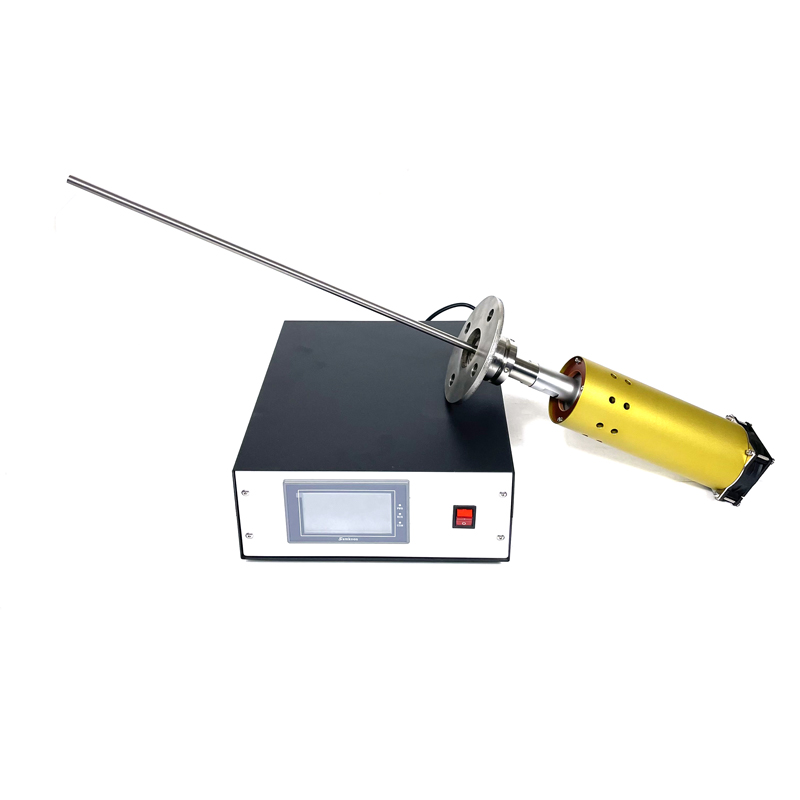

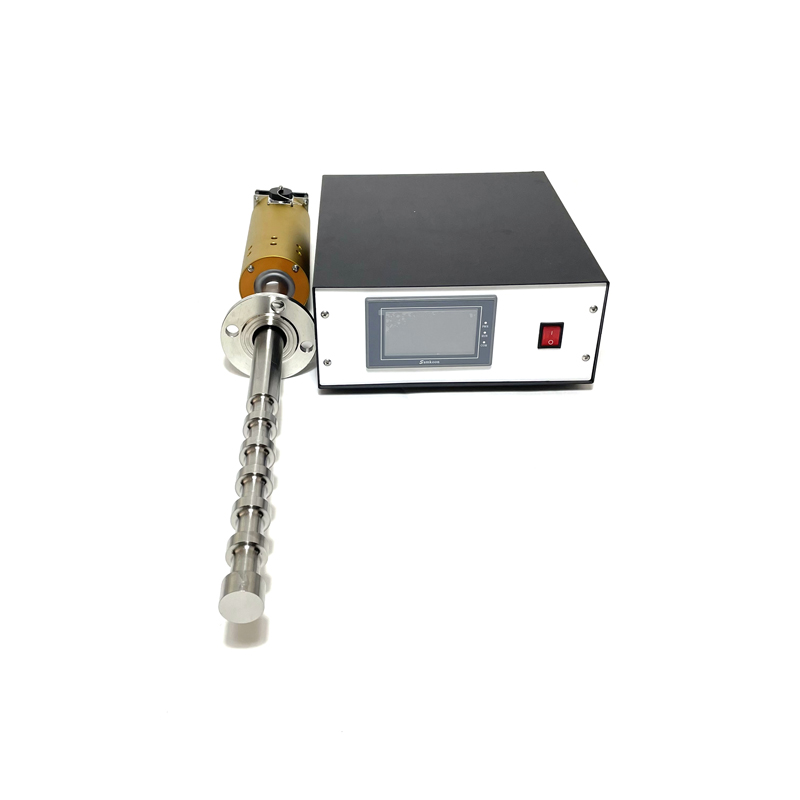

The application of ultrasonic vibration rods in the degradation of phenol organic wastewater shows that the free radicals released by ultrasonic vibration rods oxidize in water, producing organic intermediates with low toxicity or easy biodegradation. They can further oxidize and decompose into CO2 and H2O, thereby reducing the organic carbon in the wastewater and achieving the degradation goal. The addition of pollution-free strong oxidants (such as H2O2 and O3) will accelerate the degradation rate

| Tubular EquipmentType | Tubular TransducerType | Frequency(KHz) | UltrasoundOutput(W) | Total Length(mm) | Diameter(mm) | Static Capacity(pF±10%) |

| PU-UE1 | US-61 | 15-28 | 1000 | 500 | Φ50-55 | 68000 |

| PU-UE5 | US-25 | 15-28 | 1500 | 850 | Φ50-55 | 68000 |

| PU-UE6 | US-16 | 15-28 | 2000 | 1100 | Φ50-55 | 132000 |

Waste Oil Animal Fat Food Mixers Ultrasonic Mixing Equipment For Biodiesel Nanoemulsion

标签:Ultrasonic Mixing Equipment For Biodiesel Nanoemulsion, Waste Oil Animal Fat Food Mixers Ultrasonic Mixing Equipment

Send Inquiry

1200W Tubular Homogenizer Ultrasonic Disrupter For Nanoparticle Dispersion

1200W Tubular Homogenizer Ultrasonic Disrupter For Nanoparticle Dispersion 300W 20KHZ Ultrasonic Cavitation Reactor Ultrasonic Sonochemistry Biodiesel And Sound Generator

300W 20KHZ Ultrasonic Cavitation Reactor Ultrasonic Sonochemistry Biodiesel And Sound Generator Ultrasonic Biodiesel Reactor Lab Emulsifying Machine Small Lab Mixing Equipment For Nanoemulsion

Ultrasonic Biodiesel Reactor Lab Emulsifying Machine Small Lab Mixing Equipment For Nanoemulsion Titanium Alloy 1000watt Ultrasonic Extraction Equipment For Plant Essential Oil Sonochemistry Biodiesel Reactor Disperser

Titanium Alloy 1000watt Ultrasonic Extraction Equipment For Plant Essential Oil Sonochemistry Biodiesel Reactor Disperser 1000W Biosafer Nano Emulsifier Ultrasonic Homogenizer Sonicator Cosmetic Homogenizer Homogenizer Mixer

1000W Biosafer Nano Emulsifier Ultrasonic Homogenizer Sonicator Cosmetic Homogenizer Homogenizer Mixer 20KHZ 1000W Ultrasonic Tissue Extraction Machine Extractor Homogenizer Reactor

20KHZ 1000W Ultrasonic Tissue Extraction Machine Extractor Homogenizer Reactor 20KHZ 900W 220V Ultrasonic Emulsification Homogenizer Plant Oil Extraction For Nanoemulsion Mixing

20KHZ 900W 220V Ultrasonic Emulsification Homogenizer Plant Oil Extraction For Nanoemulsion Mixing 20Khz 2600W Industrial Ultrasonic Assisted Herb Extraction Dispersing Emulsification Homogenizer

20Khz 2600W Industrial Ultrasonic Assisted Herb Extraction Dispersing Emulsification Homogenizer 20KHZ 2000W 220V Ultrasonic Sonochemistry Reactor Disperser Emulsifying Homogenizer For Hemp Oil Extraction

20KHZ 2000W 220V Ultrasonic Sonochemistry Reactor Disperser Emulsifying Homogenizer For Hemp Oil Extraction Ultrasonic Homogenizer Sonicator Processor Cell Peraffin Wax Dispersion Oil In Water Emulsifier

Ultrasonic Homogenizer Sonicator Processor Cell Peraffin Wax Dispersion Oil In Water Emulsifier Ultrasonic Disruption And Extraction Ultrasonic Processor Homogenizer Mixer Extraction Sonicator Dispersion

Ultrasonic Disruption And Extraction Ultrasonic Processor Homogenizer Mixer Extraction Sonicator Dispersion Ultrasonic Assisted Extraction Machine Ultrasonic Biodiesel Reactor Extraction Dispersion Cell Crusher Homogenizer

Ultrasonic Assisted Extraction Machine Ultrasonic Biodiesel Reactor Extraction Dispersion Cell Crusher Homogenizer