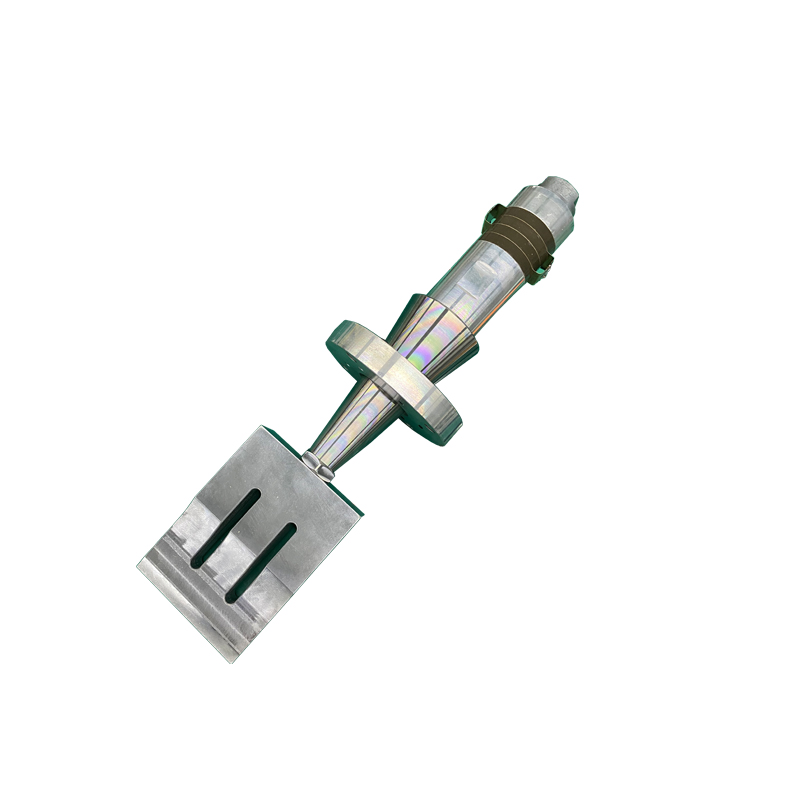

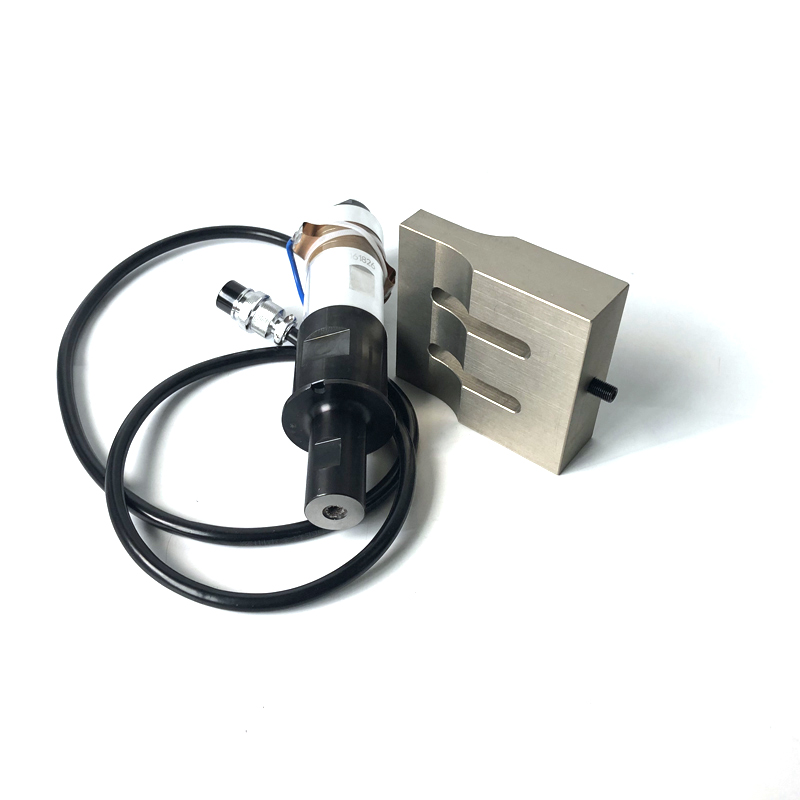

Ultrasonic Metal Welding Transducer With Booster Horn For Smart Card Ultrasonic Metal Welding Machine

Vibration frequency is one of the core parameters of the ultrasonic transducer oscillator. The selection of vibration frequency directly affects the performance and efficiency of the transducer. Generally speaking, high-frequency vibration can generate smaller wavelengths, thereby improving the resolution and accurac…

Vibration frequency is one of the core parameters of the ultrasonic transducer oscillator. The selection of vibration frequency directly affects the performance and efficiency of the transducer. Generally speaking, high-frequency vibration can generate smaller wavelengths, thereby improving the resolution and accuracy of transducers. However, high-frequency vibration is also more prone to energy loss and heat accumulation, so it is necessary to choose the appropriate vibration frequency based on actual application scenarios.

In addition to welding quality and vibration frequency, the selection of oscillator materials is also an important factor affecting the performance of ultrasonic transducers. The oscillator material needs to have characteristics such as high elasticity, high wear resistance, and high corrosion resistance to withstand long-term, high load vibration and the impact of working environment. Common oscillator materials include titanium alloy, aluminum alloy, stainless steel, etc. Choosing appropriate oscillator materials can significantly improve the service life and performance stability of transducers.

| Type | Full-length(mm) | Joint Bolt(mm) | Frequency(KHz) | Resonance Impedance(Ω) | Capacity(pF) | Input Power (W) |

| PLS-HJHNQ152600 | 153 | M20×1.5 | 15 | 15 | 13000 | 2600 |

| PLS-HJHNQ152000 | 167 | M20×1.5 | 15 | 10 | 9500 | 2000 |

| PLS-HJHNQ202000 | 128 | M18×1 | 20 | 10 | 11000 | 2000 |

| PLS-HJHNQ30500 | 77 | M10×1.5 | 30 | 5 | 5500 | 500 |

| PLS-HJHNQ28200 | 92.1 | M10×1 | 28 | 20 | 3000 | 200 |

| PLS-HJHNQ28100 | 91 | M8×1 | 28 | 25 | 2200 | 100 |

| PLS-HJHNQ28250 | 94 | 1/2-20 UNF | 28 | 20 | 4000 | 250 |

| PLS-HJHNQ202000 | 128 | 1/2-20 UNF | 20 | 10 | 20000 | 2000 |

| PLS-HJHNQ201500 | 124 | 1/2-20 UNF | 20 | 10 | 16000 | 1500 |

| PLS-HJHNQ38100 | 66 | M8×1.25 | 38 | 40 | 1200 | 100 |

| PLS-HJHNQ38200 | 65 | M8×1 | 38 | 14 | 3300 | 200 |

Send Inquiry

3000W 15KHZ Ultrasonic Welding Transducer With Booster Horn For Pet Pc Pe Ultrasonic Plastic Welding Machine

3000W 15KHZ Ultrasonic Welding Transducer With Booster Horn For Pet Pc Pe Ultrasonic Plastic Welding Machine 2000W 15KHZ Ultrasonic Welding Transducer With Booster Horn For Pvc Vinyl Ultrasonic Plastic Welding Machine

2000W 15KHZ Ultrasonic Welding Transducer With Booster Horn For Pvc Vinyl Ultrasonic Plastic Welding Machine 15KHZ/20KHZ Ultrasonic Cavitation Welder Converter Horn For Automatic Turntable Ultrasonic Welding Machine

15KHZ/20KHZ Ultrasonic Cavitation Welder Converter Horn For Automatic Turntable Ultrasonic Welding Machine 2000W 20KHZ Ultrasonic Welding Transducer With Booster For Non-woven PP PE POM Welding Machine

2000W 20KHZ Ultrasonic Welding Transducer With Booster For Non-woven PP PE POM Welding Machine Industrial Ultrasonic Welding Transducer With Booster Horn For Cards Psa Grading Card Ultrasonic Plastic Welding Machine

Industrial Ultrasonic Welding Transducer With Booster Horn For Cards Psa Grading Card Ultrasonic Plastic Welding Machine 1800W 15KHZ 20KHZ Ultrasonic Welding Transducer With Booster Horn For Plastic Lamp Packaging Carton Ultrasonic Welding Machine

1800W 15KHZ 20KHZ Ultrasonic Welding Transducer With Booster Horn For Plastic Lamp Packaging Carton Ultrasonic Welding Machine 20KHZ 2000W PZT8 High Power Ultrasonic Welding Transducer Booster Horn Vibrator Sensor For Non Woven Ultrasonic Spot Welder

20KHZ 2000W PZT8 High Power Ultrasonic Welding Transducer Booster Horn Vibrator Sensor For Non Woven Ultrasonic Spot Welder 2000W 15KHZ/20KHZ Small Ultrasonic Welder Converter Horn For Ultrasonic Welder Machine

2000W 15KHZ/20KHZ Small Ultrasonic Welder Converter Horn For Ultrasonic Welder Machine Ultrasonic Welding Transducer Sonotrodes Booster Horn For 3000W 20KHZ Ultrasonic Spin Welding Machine

Ultrasonic Welding Transducer Sonotrodes Booster Horn For 3000W 20KHZ Ultrasonic Spin Welding Machine 1800W 15KHZ/20KHZ Industrial Ultrasonic Welder Converter Horn For Ultrasonic Plastic Welder

1800W 15KHZ/20KHZ Industrial Ultrasonic Welder Converter Horn For Ultrasonic Plastic Welder 2200W 15KHZ/20KHZ Low Frequency Ultrasonic Welder Converter Horn For Rotary Ultrasonic Welding Machine

2200W 15KHZ/20KHZ Low Frequency Ultrasonic Welder Converter Horn For Rotary Ultrasonic Welding Machine 3000W 20KHZ Ultrasonic Welding Transducer With Booster Horn For Plastic Slabs Case Sealing Ultrasonic Welding Machine

3000W 20KHZ Ultrasonic Welding Transducer With Booster Horn For Plastic Slabs Case Sealing Ultrasonic Welding Machine