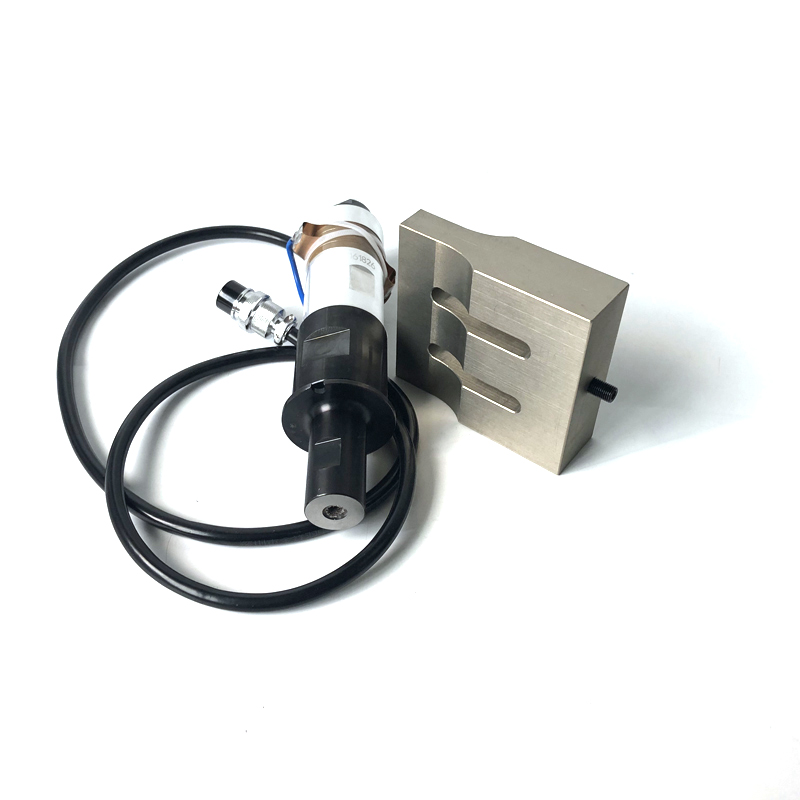

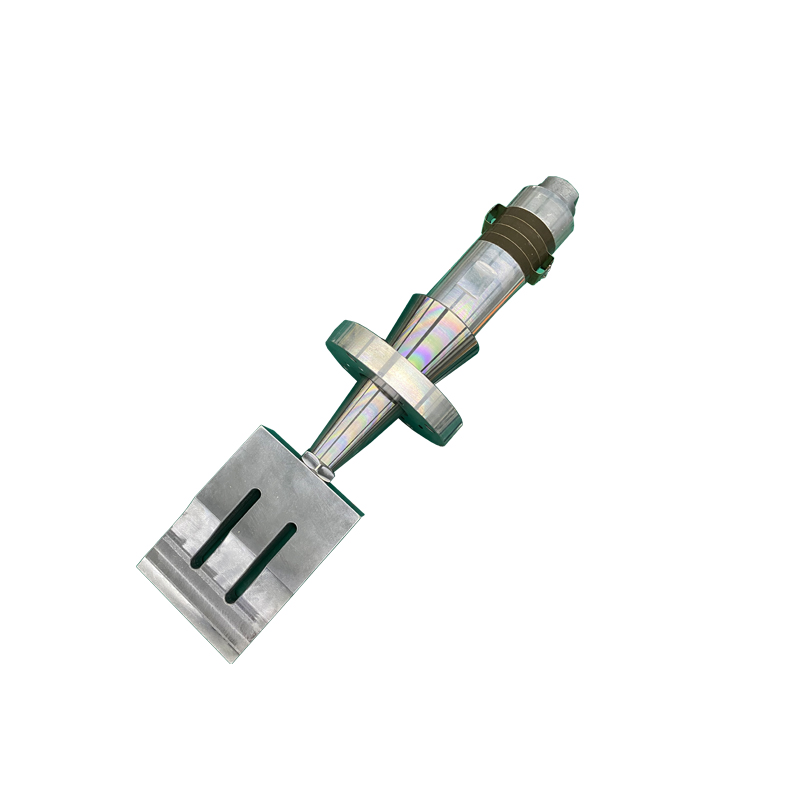

2600W 20KHZ Ultrasonic Welding Transducer Booster Horn PZT-8 Ultrasonic Transducer For Ultrasonic Plastic Welding System

Industrial ultrasonic plastic welding transducer is an efficient and environmentally friendly plastic welding equipment widely used in fields such as automobiles, electronics, healthcare, and packaging. It transfers ultrasonic energy to the plastic workpiece through high-frequency vibration, causing the plastic to ge…

Industrial ultrasonic plastic welding transducer is an efficient and environmentally friendly plastic welding equipment widely used in fields such as automobiles, electronics, healthcare, and packaging. It transfers ultrasonic energy to the plastic workpiece through high-frequency vibration, causing the plastic to generate frictional heat at the contact surface and melt, and then welding is achieved through a certain pressure. Compared to traditional hot melt welding methods, industrial ultrasonic plastic welding transducers have advantages such as higher welding strength, better sealing, lower energy consumption, and faster welding speed.

The core component of an industrial ultrasonic plastic welding transducer is the transducer, which is responsible for converting electrical energy into mechanical vibration energy. The performance of transducers directly affects the quality and efficiency of ultrasonic welding. Excellent transducers should have characteristics such as high conversion efficiency, low loss, and high stability. At the same time, the design and manufacturing of transducers also need to consider factors such as material selection, structural optimization, and thermal management to ensure that they can maintain stable performance under long-term working conditions.

| Type | Full-length(mm) | Joint Bolt(mm) | Frequency(KHz) | Resonance Impedance(Ω) | Capacity(pF) | Input Power (W) |

| PLS-HJHNQ152600 | 153 | M20×1.5 | 15 | 15 | 13000 | 2600 |

| PLS-HJHNQ152000 | 167 | M20×1.5 | 15 | 10 | 9500 | 2000 |

| PLS-HJHNQ202000 | 128 | M18×1 | 20 | 10 | 11000 | 2000 |

| PLS-HJHNQ30500 | 77 | M10×1.5 | 30 | 5 | 5500 | 500 |

| PLS-HJHNQ28200 | 92.1 | M10×1 | 28 | 20 | 3000 | 200 |

| PLS-HJHNQ28100 | 91 | M8×1 | 28 | 25 | 2200 | 100 |

| PLS-HJHNQ28250 | 94 | 1/2-20 UNF | 28 | 20 | 4000 | 250 |

| PLS-HJHNQ202000 | 128 | 1/2-20 UNF | 20 | 10 | 20000 | 2000 |

| PLS-HJHNQ201500 | 124 | 1/2-20 UNF | 20 | 10 | 16000 | 1500 |

| PLS-HJHNQ38100 | 66 | M8×1.25 | 38 | 40 | 1200 | 100 |

| PLS-HJHNQ38200 | 65 | M8×1 | 38 | 14 | 3300 | 200 |

标签:plastic, ultrasonic, welding

Send Inquiry

Piezoelectric Ultrasonic Welding Transducer With Booster Horn For Sponge Cloth Ultrasonic Plastic Welding Machine

Piezoelectric Ultrasonic Welding Transducer With Booster Horn For Sponge Cloth Ultrasonic Plastic Welding Machine Plastic Welding Ultrasonic Transducer Booster Horn For Ultrasonic Cutting Edge Sealing Machine

Plastic Welding Ultrasonic Transducer Booster Horn For Ultrasonic Cutting Edge Sealing Machine 2000W 15KHZ Ultrasonic Welding Transducer With Booster Horn For Pvc Vinyl Ultrasonic Plastic Welding Machine

2000W 15KHZ Ultrasonic Welding Transducer With Booster Horn For Pvc Vinyl Ultrasonic Plastic Welding Machine 2000W 20KHZ Ultrasonic Welding Transducer With Booster For Non-woven PP PE POM Welding Machine

2000W 20KHZ Ultrasonic Welding Transducer With Booster For Non-woven PP PE POM Welding Machine Ultrasonic Welding Transducer Sonotrodes Booster Horn For 3000W 20KHZ Ultrasonic Spin Welding Machine

Ultrasonic Welding Transducer Sonotrodes Booster Horn For 3000W 20KHZ Ultrasonic Spin Welding Machine 3200W 15KHZ/20KHZ Single Frequency Ultrasonic Welder Converter Horn For Ultrasonic Fabric Welding Machine

3200W 15KHZ/20KHZ Single Frequency Ultrasonic Welder Converter Horn For Ultrasonic Fabric Welding Machine 2500W 15KHZ/20KHZ Ultrasonic Vibrating Welder Converter Horn For Benchtop Ultrasonic Welder Machine

2500W 15KHZ/20KHZ Ultrasonic Vibrating Welder Converter Horn For Benchtop Ultrasonic Welder Machine 1000W 15KHZ/20KHZ High Power Ultrasonic Welder Converter Horn For Ultrasonic Welding Machine

1000W 15KHZ/20KHZ High Power Ultrasonic Welder Converter Horn For Ultrasonic Welding Machine Piezoelectric Ultrasonic Welding Transducer Booster Horn For Ultrasonic Plastic Tube Sealing Machine

Piezoelectric Ultrasonic Welding Transducer Booster Horn For Ultrasonic Plastic Tube Sealing Machine Industrial Ultrasonic Welding Transducer With Booster Horn For Cards Psa Grading Card Ultrasonic Plastic Welding Machine

Industrial Ultrasonic Welding Transducer With Booster Horn For Cards Psa Grading Card Ultrasonic Plastic Welding Machine 2000W 15KHZ Ultrasonic Welding Transducer With Booster Horn For Pvc Vinyl Ultrasonic Plastic Welding Machine

2000W 15KHZ Ultrasonic Welding Transducer With Booster Horn For Pvc Vinyl Ultrasonic Plastic Welding Machine Piezoelectric Ultrasonic Welding Transducer With Booster Horn For Sponge Cloth Ultrasonic Plastic Welding Machine

Piezoelectric Ultrasonic Welding Transducer With Booster Horn For Sponge Cloth Ultrasonic Plastic Welding Machine