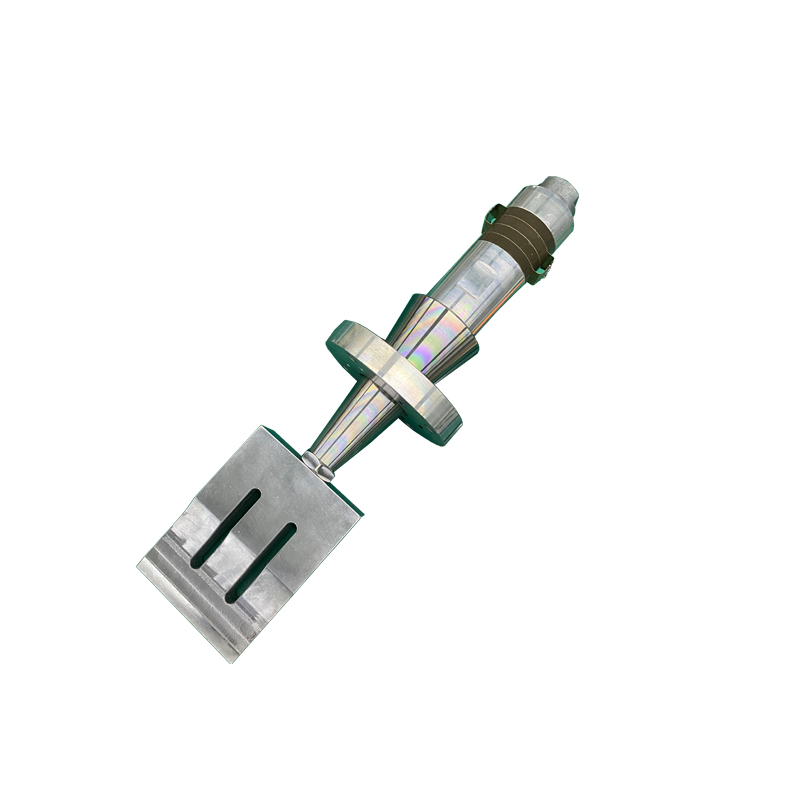

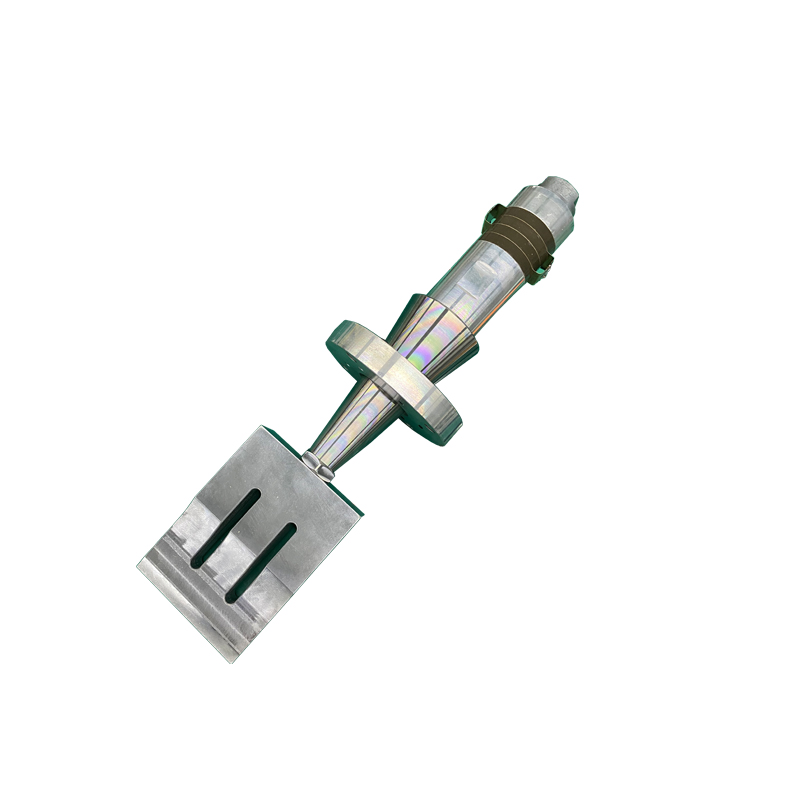

Ultrasonic Welding Transducer Booster Horn For Fabric Plastic Ultrasonic Welding Machine

In the process of welding the ultrasonic transducer oscillator, we also need to pay attention to some operational details and safety issues. For example, during the welding process, it is necessary to wear protective goggles and gloves to avoid injuries caused by flying sparks and high temperatures. In addition, afte…

Ultrasonic Welding Transducer Booster Horn For Fabric Plastic Ultrasonic Welding Machine

In the process of welding the ultrasonic transducer oscillator, we also need to pay attention to some operational details and safety issues. For example, during the welding process, it is necessary to wear protective goggles and gloves to avoid injuries caused by flying sparks and high temperatures. In addition, after welding is completed, a comprehensive inspection and testing of the transducer is required to ensure that its performance meets the requirements and is safe and reliable.

Welding ultrasonic transducer oscillators is a complex and important process. We need to have a thorough understanding of welding technology, vibration frequency, oscillator materials, and strictly follow the operating procedures to ensure that the welded transducer has excellent performance and stability. At the same time, we also need to pay attention to safety issues and operational details to avoid unexpected situations during the welding process.

| Type | Full-length(mm) | Joint Bolt(mm) | Frequency(KHz) | Resonance Impedance(Ω) | Capacity(pF) | Input Power (W) |

| PLS-HJHNQ152600 | 153 | M20×1.5 | 15 | 15 | 13000 | 2600 |

| PLS-HJHNQ152000 | 167 | M20×1.5 | 15 | 10 | 9500 | 2000 |

| PLS-HJHNQ202000 | 128 | M18×1 | 20 | 10 | 11000 | 2000 |

| PLS-HJHNQ30500 | 77 | M10×1.5 | 30 | 5 | 5500 | 500 |

| PLS-HJHNQ28200 | 92.1 | M10×1 | 28 | 20 | 3000 | 200 |

| PLS-HJHNQ28100 | 91 | M8×1 | 28 | 25 | 2200 | 100 |

| PLS-HJHNQ28250 | 94 | 1/2-20 UNF | 28 | 20 | 4000 | 250 |

| PLS-HJHNQ202000 | 128 | 1/2-20 UNF | 20 | 10 | 20000 | 2000 |

| PLS-HJHNQ201500 | 124 | 1/2-20 UNF | 20 | 10 | 16000 | 1500 |

| PLS-HJHNQ38100 | 66 | M8×1.25 | 38 | 40 | 1200 | 100 |

| PLS-HJHNQ38200 | 65 | M8×1 | 38 | 14 | 3300 | 200 |

Ultrasonic Welding Transducer Booster Horn For Fabric Plastic Ultrasonic Welding Machine

Send Inquiry

Piezoelectric Ultrasonic Welding Transducer Booster Horn For High Power Ultrasonic Plastic Welding Machine

Piezoelectric Ultrasonic Welding Transducer Booster Horn For High Power Ultrasonic Plastic Welding Machine Industrial Ultrasonic Welding Transducer With Booster Horn For Cards Psa Grading Card Ultrasonic Plastic Welding Machine

Industrial Ultrasonic Welding Transducer With Booster Horn For Cards Psa Grading Card Ultrasonic Plastic Welding Machine 20KHZ 3000W Piezoelectric Ceramic Ultrasonic Welding Transducer Booster Horn For Automatic Ultrasonic Plastic Welding Machine

20KHZ 3000W Piezoelectric Ceramic Ultrasonic Welding Transducer Booster Horn For Automatic Ultrasonic Plastic Welding Machine 2200W 15KHZ/20KHZ Low Frequency Ultrasonic Welder Converter Horn For Rotary Ultrasonic Welding Machine

2200W 15KHZ/20KHZ Low Frequency Ultrasonic Welder Converter Horn For Rotary Ultrasonic Welding Machine 2000W 15KHZ Ultrasonic Welding Transducer With Booster Horn For Pvc Vinyl Ultrasonic Plastic Welding Machine

2000W 15KHZ Ultrasonic Welding Transducer With Booster Horn For Pvc Vinyl Ultrasonic Plastic Welding Machine 15KHZ/20KHZ Ultrasonic Cavitation Welder Converter Horn For Automatic Turntable Ultrasonic Welding Machine

15KHZ/20KHZ Ultrasonic Cavitation Welder Converter Horn For Automatic Turntable Ultrasonic Welding Machine 2000W 15KHZ Ultrasonic Welding Transducer With Booster Horn For Pvc Vinyl Ultrasonic Plastic Welding Machine

2000W 15KHZ Ultrasonic Welding Transducer With Booster Horn For Pvc Vinyl Ultrasonic Plastic Welding Machine 2000W 20KHZ Ultrasonic Welding Transducer With Booster For Non-woven PP PE POM Welding Machine

2000W 20KHZ Ultrasonic Welding Transducer With Booster For Non-woven PP PE POM Welding Machine 3000W 15KHZ Ultrasonic Welding Transducer With Booster Horn For Pet Pc Pe Ultrasonic Plastic Welding Machine

3000W 15KHZ Ultrasonic Welding Transducer With Booster Horn For Pet Pc Pe Ultrasonic Plastic Welding Machine Ultrasonic Plastic Welding Transducer Booster Horn For Turntable Ultrasonic Plastic Welding Machine

Ultrasonic Plastic Welding Transducer Booster Horn For Turntable Ultrasonic Plastic Welding Machine Ultrasonic Plastic Welding Transducer With Booster Horn For ABB ABS PP Ultrasonic Plastic Welding Machine

Ultrasonic Plastic Welding Transducer With Booster Horn For ABB ABS PP Ultrasonic Plastic Welding Machine Plastic Welding Ultrasonic Transducer Booster Horn For Ultrasonic Cutting Edge Sealing Machine

Plastic Welding Ultrasonic Transducer Booster Horn For Ultrasonic Cutting Edge Sealing Machine